Mine Tailings Dredging

We provide Mine Tailing Dredging and consulting services

Dredging Services |

GET STARTED

Contact us about dredge engineering, equipment, pumping, and dewatering to

meet your contract

requirements.

Tailing Ponds

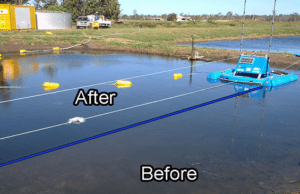

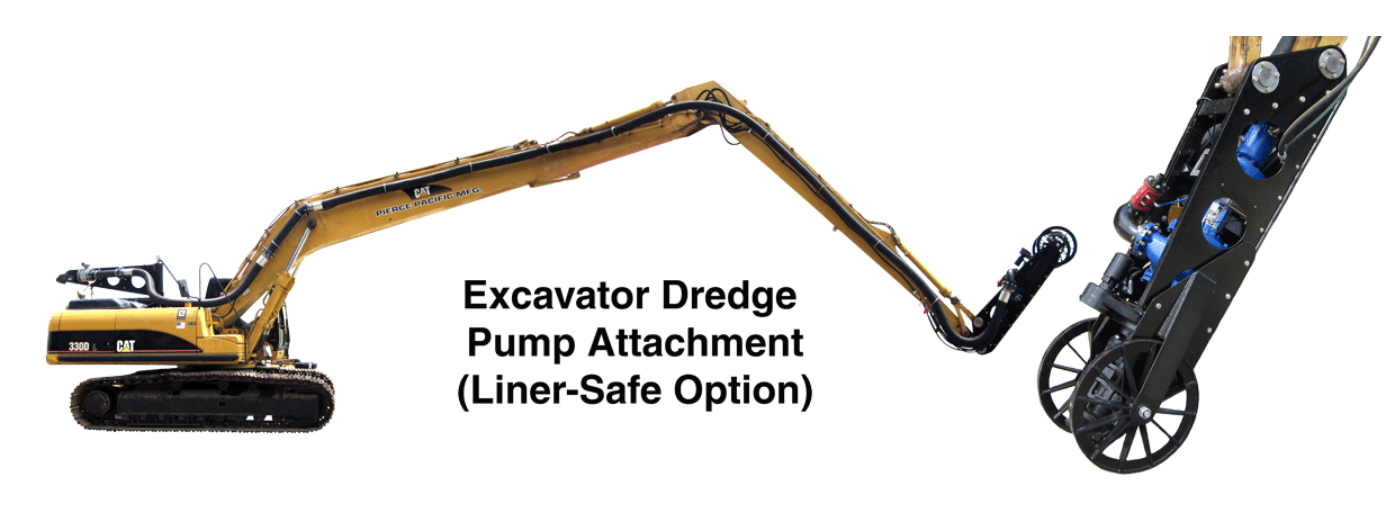

Mining operations produce large volumes of waste and debris referred as “tailings” that end up at the bottom of containment ponds and lagoons. We offer specialty dredging equipment and services designed to desilt and desludging a range of slime ponds, tailings lagoons, and contained waterways at mine sites.

Tailings Dredge

Dredging can be a very effective and economical means of extracting tailings from a storage facility.

For decades, mines have been dealing with their waste by disposing of tailings in a pond. Today, the materials in these tailing ponds are seen as valuable and potentially usable. If mines extract them, they can use them.

Benefits of Tailing Pond Dredging:

- Value Recovery: Instead of disposing of it, processing waste through dredging and dewatering allows mines to recover minerals that can be reused in the mine’s processes.

- Environmental Performance: At the end of the day, these solutions are turning waste into raw material and products. It has never been more crucial for companies in the mining sector to abide by increasingly stricter environmental regulations, and go above and beyond compliance to build a profile as sustainability leaders.

- Cost Savings: More often than not, our environmental solutions enable mines to recover and reuse enough product to cover the costs of the services, and then some.

- Convenience: By bringing solutions onsite to mining locations, we are providing customers with a safe, convenient, turn-key approach to managing and processing their waste onsite.

Tailings Contractor

P&S has extensive experience performing mine remediation projects in accordance with CERCLA/RCRA and other federal, state, and location regulations.

One example customer is a coal mine that requested a machine capable of dredging sediments from three ponds where all the storm water of the mine was collected, as well as the water coming from the mining machines.

The drainage pumps currently used were not able to remove the solid material from the bottom of the ponds, affecting the capacity of the ponds which was continuously decreasing.

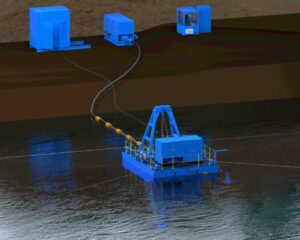

The dredging system had to be remote controlled and capable of removing the settled fine sediment from the bottom.

Our solution

Pump and Slurry supplied a remote controlled dredge equipped with a high chrome, high solids slurry pump with a jetting ring that is capable of mixing the fine material through pressurized water jets.

Tailings Consulting Services

Often tailings ponds can be neglected for decades. We have the experience and equipment to bring it back up to full storage capacity and meet all local, State and Federal guidelines. Contact us Pump and Slurry Tailing Pond Services at 619-315-6310.

- Site evaluation

- Geotechnical, hydrogeologic, rheologic, and geochemical evaluation and characterization

- Risk and hazard assessment and emergency response planning

- Construction and operation monitoring, management, and quality assurance

- Decommissioning, closure, and landform restoration

- Tailing pond dredges, pumps and service.

GET STARTED

Contact us about dredging consulting, equipment, pumping and dewatering to meet your contract requirements.