Slurry Transport |

GET STARTED

Contact us about dredge engineering, equipment, pumping, and dewatering to

meet your contract

requirements.

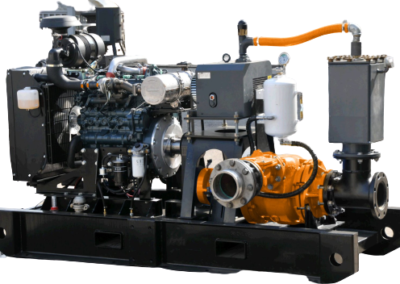

High Solids Pumps for Your Project

Based on decades of engineering and manufacturing of slurry pumps and systems for some of the largest government agencies and companies in the world, there is nobody with more experience than P&S.

Our engineering design never stopped at just the pump or system, but also full automation of all systems bringing them to IoT status that allows the systems to be monitored and run from anywhere in the world remotely. We can design the systems ground up with the best pumps, piping, valves, power, and automation.

The task that we face when designing a pump system is to size a pump of sufficient capacity for the job and to find the correct style or configuration for your application and service. Everything we attach to the pump has an impact such as tank size and level location with respect to the pump, pipe sizes, and material and flow rate required.

Our goal is to achieve the desired flow rate under the conditions that are imposed. As a pump manufacturer and distributor of pumps, we understand how pumping works and have the staff on hand to support your applications and requirements. Our pumps are designed to be used in demanding applications and places where there is no option for downtime.

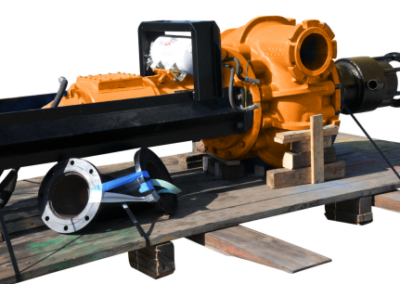

Centrifugal Slurry Pumps

Pumps are designed in a manner that allows the pump to operate continuously for months or even years. These centrifugal pumps often rely on the liquid that they are pumping to provide cooling and lubrication to the pump bearings and other internal components of the pump.

For a given centrifugal pump operating at a constant speed, the flow rate through the pump is the Characteristic Curve dependent upon the differential pressure or head developed by the pump. The lower the pump head, the higher the flow rate.

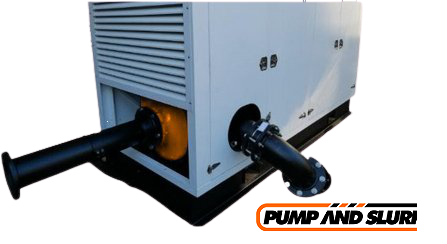

When a centrifugal pump is installed in a system such that it may be subjected to periodic shutoff head conditions, it is necessary to provide some means of pump protection. One method for protecting the pump from running dead-headed is to provide a recirculation line from the pump discharge line upstream of the discharge valve, back to the pump’s supply source. The recirculation line should be sized to allow enough flow through the pump to prevent overheating and damage to the pump. Protection may also be accomplished by use of an automatic flow control device.

- Positive Displacement

- Automated Controls

- Concrete Slurry Dewatering

- High Solids Pump

- Pump Calculations

- Solids Pumping

- Sludge Dewatering

- Dredge Pump Rental

- Hydrographic Survey

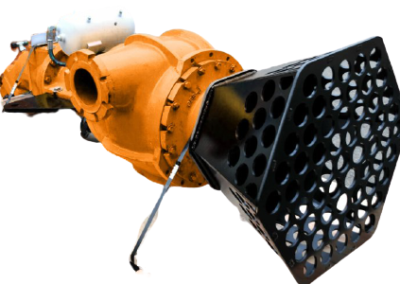

Most centrifugal pumps are not self-priming. In other words, the pump casing must be filled with liquid before the pump is started, or the pump will not be able to function. If the pump casing becomes filled with vapors or gases, the pump impeller becomes gas-bound and incapable of pumping. To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. The same effect can be gained by supplying liquid to the pump suction under pressure supplied by another pump placed in the suction line.