Dredging Services |

GET STARTED

Contact us about dredge engineering, equipment, pumping, and dewatering to

meet your contract

requirements.

INDUSTRY PROBLEM

The issue with most barge unloading dredging equipment is sanding up when faced with drier materials or coarse materials that include rocks and other heavy aggregates.

Operators try to avoid sanding up by adding more water to the dredged materials, adding more bulk and leading to additional time to move and dewater, reducing capacity in the name of avoiding downtime and difficult manual intervention.

OUR UNIQUE SOLUTION

Benefits

- Pump materials with only 30% moisture content and cohesive materials without having to add too much additional water.

- Operate by crane, excavator, or stationary

- Increase your transport distance, we offer a full line of booster pumps from 1 to 12 inches.

- High production capacity, the special rotary head breaks up materials and moves them out, making your life easier.

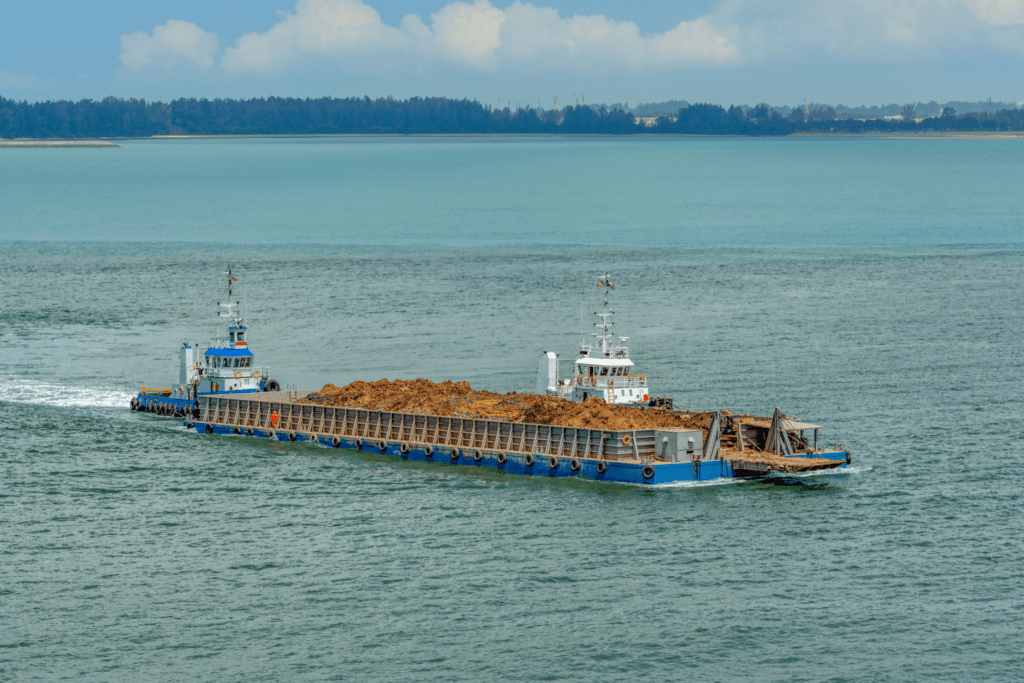

Our dredging equipment is used for emptying loaded barges either by crane with the cutter dredger hanging or by suction dredgers or by bucket ladder dredgers and cranes. The barge-unloading dredger is a stationary special suction dredger anchored by spuds near the shore, where the water depth is enough for the loading barges to come alongside the dredger. The water for the unloading and the transport is supplied into the barge by a jet.

Barge Unloading Facts

GET STARTED

Contact us about dredging consulting, equipment, pumping and dewatering to meet your contract requirements.