Tank Systems

Bring your dewatering system to residential, city and any jobsites with good roads

Dewatering Tank Benefits

Dewatering tanks offer a cost-effective solution for situations in which pumps are not available and sludge needs to be dewatered and transported.

- Construction

- Horizontal Drilling and Boring

- Liquid Containment

- Pipeline

- Emergency Response

- Groundwater

Hydro-tested containers in a range of sizes and functions:

- 25 Yard Canvas Tarp Roll-Off Container

- 25 Yard Steel Hard-Top Roll-Off Container

- 25 Yard Dewatering Vacuum Box

Store hazardous and non-hazardous liquids, such as contaminated groundwater or stormwater runoff. Ideal for sediment separation and slurry containment.

- Can be used in conjunction with pumps, filters, dewatering units and vacuum boxes as part of a large scale project

- Can be used in large clean up operations, oil field operations or simply for temporary storage of water or other liquids

- DOT registered vehicle and easily transported by a tractor with a winch and fifth wheel attachment

Dewatering and Solids Separation

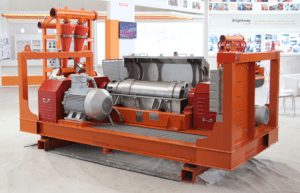

Solids Separation Systems

Dewatering and separating solids in tight confines and those who require a faster dewatering and separation solution, we build out an integrated system to fit your space requirements.

Decanting Centrifuges

This offers you the opportunity to dewater to a greater level your slurry and make a cake that is easier to transport and less costly to dispose of.

Hydrocyclones

Remove solids from your slurry stream with the simple physics of Hydrocyclones. This is a high speed option to separate your water from solids.

Shale Shakers and Shaker Screens

Immediately remove large solids and dewater from your slurry stream as part of your separation process.