Decanting Centrifuges

By removing more water and producing a drier cake product, dewatering will offer significant savings in treatment, handling, and disposal costs.

Slurry Dewatering |

GET STARTED

Contact us about dredge engineering, equipment, pumping, and dewatering to

meet your contract

requirements.

Slurry Dewatering Centrifuge

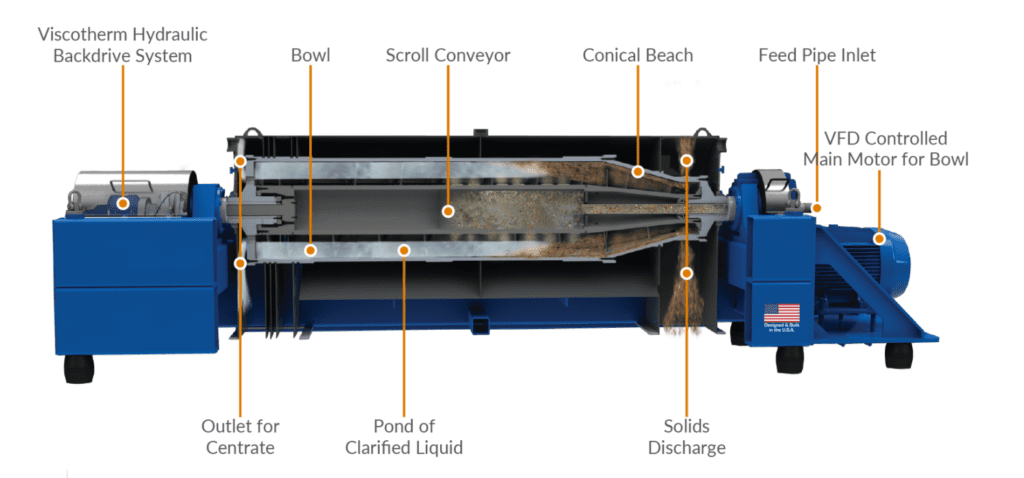

Sludge dewatering centrifuge uses a fast rotation of a “cylindrical bowl” to separate wastewater liquid from solids. The wastewater centrifuge dewatering process removes more water than other methods and leaves solid material that is known as cake.

Also referred to as:

- Decanting Centrifuge

- Horizontal Spiral Centrifuge

- Horizontal Decanter Centrifuge

- Centrifuge Separator

Using a high-speed and continual rotational process the decanting centrifuge the suspending fluids are pushed into the rotor drum through the inlet pipe and the fluid hole of the spiral feeder. Under the influence of centrifugal force, solid phase particles are pushed to the internal wall of the drum, then to the mud export of the small end of the drum and excreted.

The principle of a centrifuge, also known as a centrifugal decanter, is to use centrifugal force to accelerate solid-liquid separation.

To simplify, it can be assumed that a centrifuge is a conical cylinder decanter that turns horizontally on its axis with a clarified water overflow, the dewatered sludge being removed by an Archimedean screw. The rotation applies a centrifugal force on the solid particles that then move a lot more quickly.

In practice, the flocculated sludge is injected inside the centrifuge bowl through an injection pipe. The bowl has a high rotation speed (3500 rpm) and the particles are flattened against the bowl’s sides in the clarification zone. The particles are then pushed by an Archimedean screw towards the end of the bowl’s cone in the sludge spin-dry zone. The clarified liquid called, centrate, is evacuated at the other end of the bowl by overflow.

GET STARTED

Contact us about dredging consulting, equipment, pumping and dewatering to meet your contract requirements.