Non-Newtonian Liquids

A slurry is a liquid containing SOLID particles whilst a liquor contains DISSOLVED particles. Pumping solids raises different requirements for a pump compared to pumping just a liquid.

Except for density the characteristics of a liquid are decided by its viscosity.

Liquids deform continuously as long as a force is applied to them. They are said to flow. When a flow takes place in a liquid, it is opposed by internal friction arising from the cohesion of the molecules. This internal friction is the property of a liquid called viscosity.

In most liquids, the viscosity decreases rapidly with increasing temperature.

Some liquids, such as water based slurries with VERY fine particles, do not obey the simple relationship between shearing stress and shearing rate (compare nonsettling slurry). They are referred to as non-Newtonian liquids.

Yield Stress

Some non-Newtonian liquids have a unique property of not flowing until a certain minimum shear stress is applied. This minimum shear stress is known as the yield stress. Consider fine wet beach sand at the shore break (or in the extreme quicksand). When you stand on it, it remains hard. Stamp your feet on it, and it turns to liquid and you start sinking. The slurry needed an initial energy input to enable it to begin to act as a flowable product.

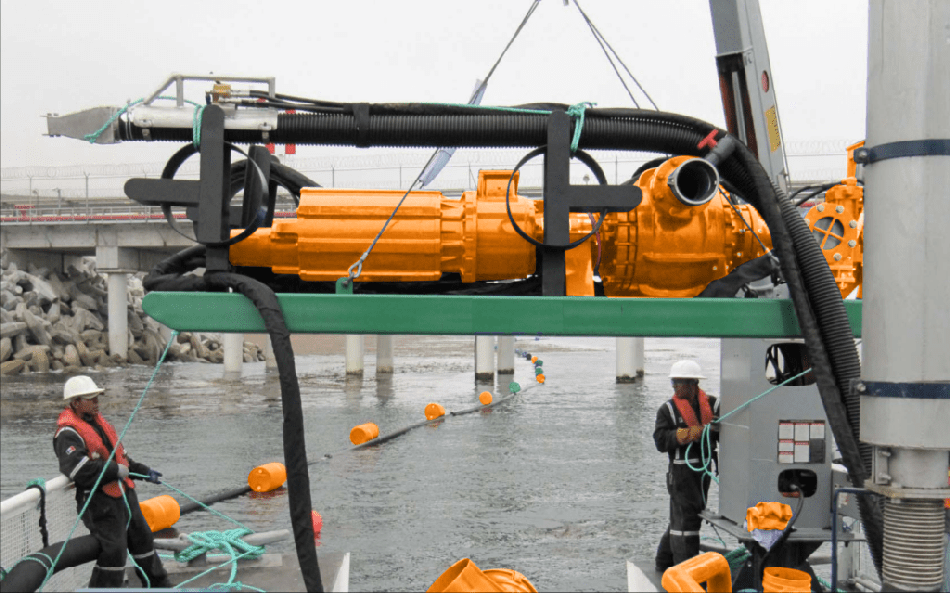

Slurry Categories

Slurry pumping can usually be separated into four categories which ANSI/HI Standard 12.1-12.6-2005 categorizes as light slurries (Class 1), medium slurries

(Class 2), heavy slurries (Class 3) and very heavy slurries (Class 4).

Most usually the light (Class 1) slurries are those not deliberately intended to carry solids. The presence of the solids occurs more by accident than design. On the other hand, very heavy slurries (Class 4) are those normally designed specifically to transport solids from one location to another. Very often the

carrying fluid in very heavy slurry is just a necessary evil in helping to transport the desired material. The medium (Class 2) and heavy slurry (Class 3) fall somewhere in between.

The optimum slurry pump material will often vary even across a single processing plant that is transferring the same solids (but having different sizes). For example a single processing plant may use all white iron ‘Mill Discharge’ pumps, through to a rubber lined pumps with urethane impeller to dispose of the tailings. The same solids are being transferred, often with the same or a very similar carrying fluid, but different slurry pump wear materials will be required.

Slurry Pump Selection

Considerations that need to be addressed when selecting a pump model and its materials include:

• Abrasive hardness

• Particle shape

• Particle size

• Particle velocity and direction

• Particle density

• Particle sharpness

• Concentration of Solids by Weight or Volume

• Temperature of slurry

• Corrosive nature of carrier fluid/slurry

View Slurry Transport pumps