Dewatering pumps play a critical role in various industrial applications, particularly where the removal of excess water and the management of slurry are essential. These pumps are crucial for industries such as mining, construction, and wastewater treatment, where managing high solids and slurry can significantly impact operations. The challenge of dealing with high solids and slurry lies in their abrasive nature, which can wear down pump components and affect efficiency. Energy-efficient dewatering pumps, including specialized sludge dewatering pumps, are designed to tackle these challenges by offering enhanced durability, reliability, and lower operational costs.

Understanding Dewatering Pumps

Dewatering pumps are specifically engineered to remove water from solid material or ground areas, making them essential in environments where water accumulation poses a problem. These pumps come in various types, each suited for different applications, especially when high solids and slurry are involved. For industries that may not require a permanent solution, dewatering pump rental options are available, providing flexibility and cost-effectiveness.

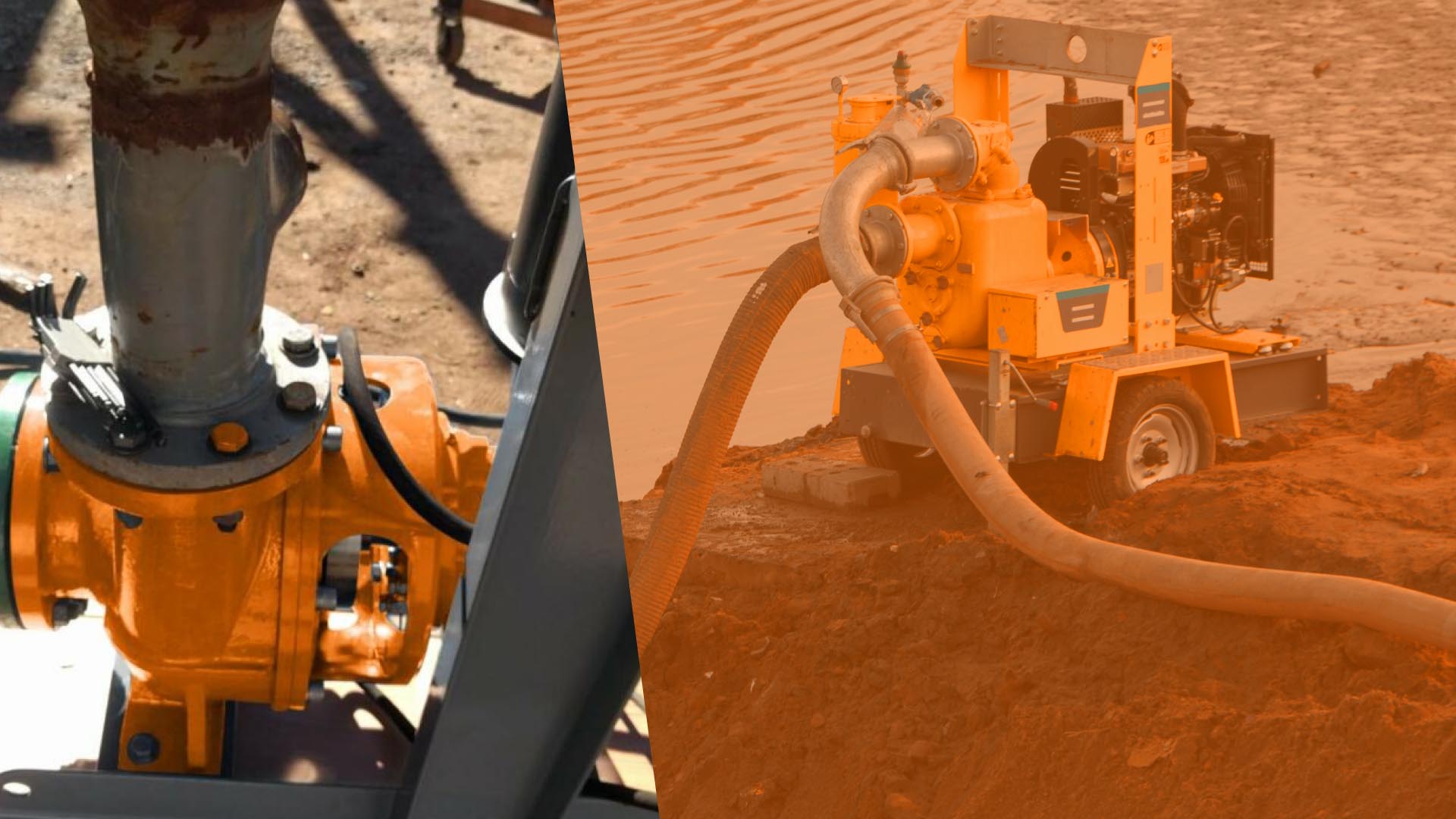

- Submersible Dewatering Pumps: These pumps are submerged directly into the slurry or water, making them ideal for applications where the pump needs to operate underwater or within a fluid. Their sealed design prevents damage from water ingress and ensures efficient operation in challenging conditions.

- Centrifugal Dewatering Pumps: Centrifugal pumps use rotational energy to move fluids. They are widely used in applications where high flow rates are required. While effective, they may struggle with very high solids content, which can cause wear and reduce efficiency.

- Positive Displacement Dewatering Pumps: Unlike centrifugal pumps, positive displacement pumps move fluid by trapping a fixed amount and displacing it into the discharge pipe. These pumps are well-suited for handling thick slurries and high solids due to their ability to maintain consistent flow rates despite varying viscosities.

Challenges in Managing High Solids and Slurry

- Abrasion and Wear on Pump Components: Slurries containing abrasive particles like sand, gravel, or minerals can wear down pump components, leading to frequent maintenance and reduced lifespan.

- Handling Varying Particle Sizes and Densities: Slurries often consist of particles of different sizes and densities, making it difficult for pumps to maintain a consistent flow. This inconsistency can lead to blockages, reduced efficiency, and increased energy consumption.

- Maintaining Consistent Flow Rates: High solids content can cause fluctuations in flow rates, which impact the pump’s overall performance. Maintaining a steady flow is crucial for ensuring efficient operation and minimizing downtime.

The impact of these challenges on pump efficiency and longevity cannot be overstated. By addressing these issues, sludge dewatering pumps and other similar dewatering equipment can become efficient. However, they will require more energy to operate, leading to higher operational costs and more frequent repairs.

The Importance of Energy Efficiency in Dewatering Pumps

- Reduced Operational Costs: Energy-efficient dewatering pumps consume less power, leading to lower electricity bills. In industries where pumps run continuously, this can result in substantial savings over time.

- Lower Environmental Impact: Energy-efficient pumps reduce the carbon footprint of industrial operations by consuming less energy, contributing to sustainability goals.

- Improved Pump Lifespan and Reliability: Pumps designed for energy efficiency often incorporate advanced materials and technologies that reduce wear and tear, leading to longer service life and less frequent maintenance.

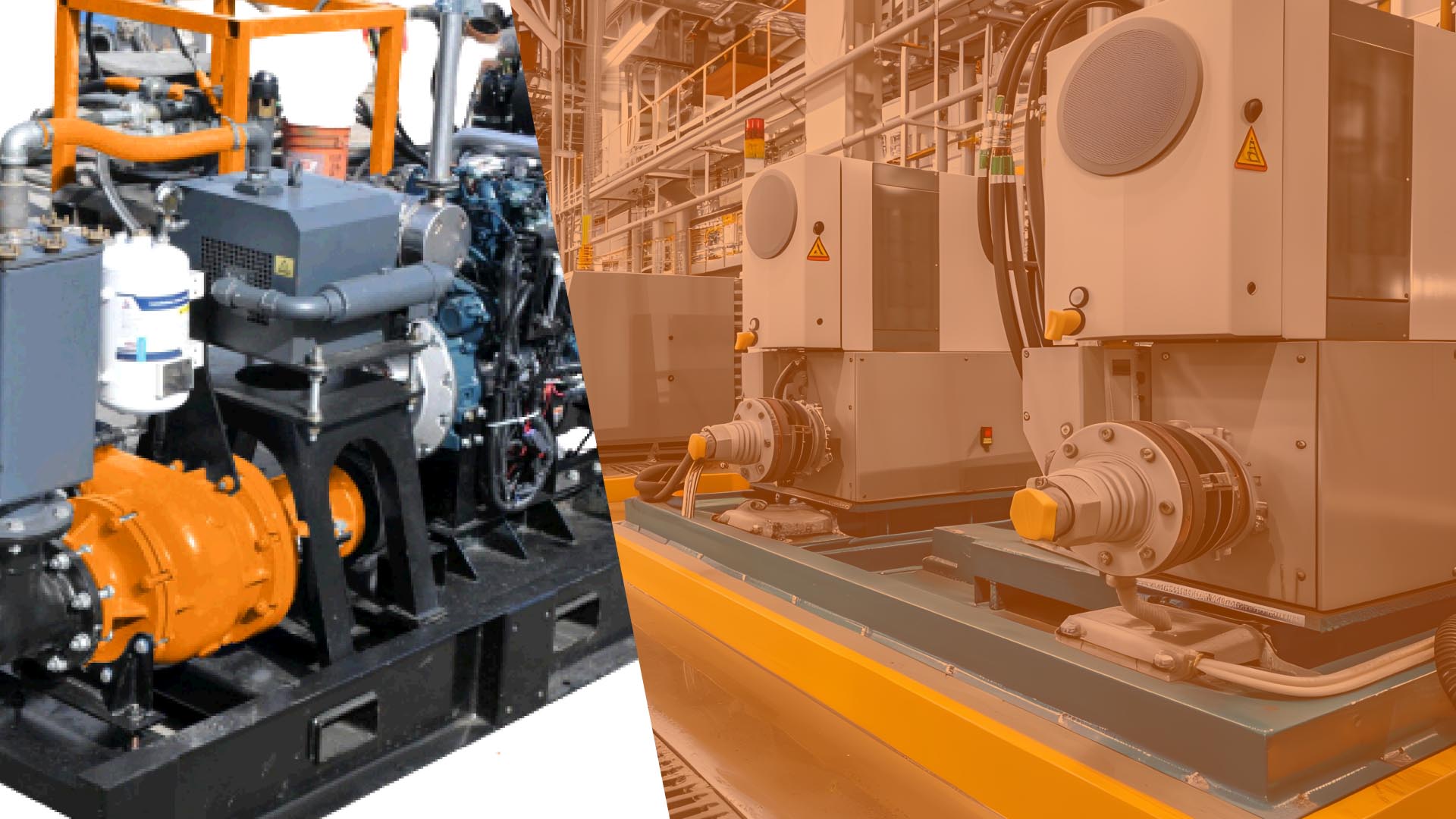

Innovations in Energy-Efficient Dewatering Pumps

- Variable Frequency Drives (VFDs): VFDs allow pumps to operate at varying speeds, adjusting the power usage according to the demand. This optimization reduces energy consumption and wear on the pump.

- Advanced Materials and Coatings: Modern pumps use durable materials and protective coatings that resist abrasion and corrosion, extending their life and maintaining efficiency.

- Smart Monitoring Systems: These systems provide real-time data on pump performance, enabling operators to make adjustments that enhance efficiency and prevent damage.

Case studies have shown that implementing these innovations can lead to significant energy savings and operational improvements, making them a wise investment for industries dealing with high solids and slurry. Even when considering dewatering pump rental, opting for energy-efficient options can yield long-term benefits.

Selecting the Right Dewatering Pump for High Solids and Slurry Applications

Choosing the right dewatering pump is critical for effectively managing high solids and slurry. Several factors must be considered:

- Pump Capacity and Performance Requirements: Ensure the pump can handle the volume and type of slurry in your specific application. Consider the flow rate, head pressure, and the pump’s ability to manage solids.

- Compatibility with Specific Slurry Types: Different slurries have unique characteristics that require specific pump designs. Choose a pump that can handle the particular solids content and viscosity of your slurry.

- Energy Efficiency Ratings and Certifications: Look for pumps that are certified for energy efficiency. These will provide long-term savings and are often built with the latest technology.

Evaluating these factors and understanding your application’s specific needs will help you select the most efficient and cost-effective dewatering equipment or dewatering pump rental option.

Maintenance and Best Practices for Maximizing Efficiency

To ensure your dewatering pumps operate at peak efficiency, regular maintenance, and best practices are essential:

- Routine Inspection and Cleaning: Regularly inspect the pump for signs of wear or damage and clean any accumulated debris to prevent blockages.

- Monitoring for Wear and Tear: Monitor critical components like seals, impellers, and bearings and replace them as needed to maintain efficiency.

- Scheduled Component Replacements: Implement a schedule for replacing components before they fail, reducing the risk of unexpected downtime.

- Best Practices for Operation: Adjust pump settings to match the slurry’s specific conditions, ensure proper installation, and train staff on energy-efficient operation techniques.