Pumping and Dredging Project Consultation in Zimbabwe | Pump and Slurry

Zimbabwe’s primary industries encompass mining, steel production, wood products, cement manufacturing, chemicals, fertilizer production, and beverages. These sectors collectively rely on efficient pumping, dredging, and dewatering services to sustain operations. In mining, a cornerstone of Zimbabwe’s economy, pumping systems are crucial for groundwater control and the transportation of ore slurries during extraction and processing. Dredging activities are essential for maintaining tailings dams and water reservoirs and vital for managing wastewater and process fluids. Dewatering services are critical in regulating groundwater levels to prevent flooding in mines, ensuring safe working conditions and uninterrupted production. These services are equally indispensable in the steel, wood products, cement, chemicals, fertilizer, and beverages industries. They facilitate the management of water resources, support manufacturing processes, and comply with environmental regulations. Overall, efficient pumping, dredging, and dewatering services are fundamental for Zimbabwe’s industrial sectors, enabling sustainable development and economic growth while safeguarding the environment.

Pumping and Dredging Project Consultation in Vietnam

Slurry pumping and dredging projects in Zimbabwe are crucial for effectively operating its key industries, such as mining, steel production, and cement manufacturing. These projects are essential for handling and transporting abrasive materials like ore slurries in mining operations, ensuring continuous production, and minimizing downtime due to blockages or inefficiencies. Dredging projects are vital in maintaining water reservoirs and tailings ponds, which are crucial for storing and managing process fluids and wastewater. By implementing robust slurry pumping and dredging projects, Zimbabwe enhances its industrial capabilities, supports economic growth, and ensures sustainable resource management practices across critical sectors.

The sales and rentals of slurry pumps and dredging equipment in Zimbabwe cater to the diverse needs of its industrial landscape, providing essential tools for pumping and dredging projects across mining, construction, and infrastructure sectors. Sales of slurry pumps ensure continuous availability of reliable equipment tailored to specific project requirements, facilitating efficient operations and reducing maintenance costs over time. Alternatively, rental services offer flexibility for businesses to manage variable demand and project durations without significant upfront investments. Both sales and rentals contribute to Zimbabwe’s industrial efficiency by supporting timely project execution, enhancing productivity, and maintaining environmental stewardship standards through effective pumping and dredging solutions.

Our Services

Consulting Services

Pumping & Slurry Transport

Dredging Consulting

Dewatering

Equipment Sales & Rentals

Equipment Rental

Equipment for Sale

Customization Services

Industries in Zimbabwe Requiring Slurry Pumping, Dredging, and Dewatering

Mining

Mining is a foundational industry in Zimbabwe, and efficient pumping, dredging, and dewatering are critical for its operations. Pumping systems are essential for groundwater control and transporting ore slurries during extraction and processing. These systems ensure continuous mining operations and minimize the risk of flooding in underground mines. Dredging activities are crucial for maintaining tailings dams and water reservoirs and storing and managing wastewater and process fluids. Dewatering systems manage groundwater levels to prevent mine flooding, ensuring safe working conditions and operational continuity. Efficient pumping, dredging, and dewatering practices optimize production output, minimize environmental impact, and sustain Zimbabwe’s mining sector.

Steel

In Zimbabwe’s steel industry, efficient pumping, dredging, and dewatering are vital for various manufacturing processes. Pumping systems facilitate the circulation of cooling water and process fluids essential for steel production, ensuring operational efficiency and product quality. Dredging activities may be necessary to maintain water channels for transportation and cooling purposes, supporting logistical operations and environmental management efforts. Dewatering systems handle wastewater and industrial effluents, ensuring compliance with environmental regulations and reducing pollution. These practices uphold operational reliability and environmental sustainability in Zimbabwe’s steel manufacturing sector.

Wood Products

Efficient pumping, dredging, and dewatering are essential in Zimbabwe’s wood products industry. Pumping systems manage fluid circulation, crucial for wood processing operations and optimizing production efficiency and product quality. Dredging activities may be required to clear water channels for transportation and processing, ensuring uninterrupted operations. Dewatering systems handle wastewater and manage water levels, adhering to environmental standards and minimizing ecological impact. These practices support sustainable wood products manufacturing in Zimbabwe, ensuring resource efficiency and environmental responsibility.

Cement

Zimbabwe’s cement industry relies on efficient pumping, dredging, and dewatering for production processes. Pumping systems transport raw materials and process fluids essential for cement manufacturing, ensuring continuous supply and operational efficiency. Dredging activities maintain water channels for transportation and cooling purposes, supporting logistical operations. Dewatering systems manage wastewater and industrial effluents, meeting environmental regulations and minimizing pollution. These practices enhance operational reliability and environmental sustainability in Zimbabwe’s cement production sector.

Chemicals

Efficient pumping, dredging, and dewatering are critical in Zimbabwe’s chemical industry. Pumping systems facilitate fluid transport essential for chemical processes, ensuring operational efficiency and product consistency. Dredging activities may be necessary to clear water pathways for logistics and environmental management. Dewatering systems handle industrial effluents, ensuring compliance with environmental standards and reducing environmental impact. These practices uphold operational reliability and environmental stewardship in Zimbabwe’s chemical manufacturing sector.

Fertilizer

Zimbabwe’s fertilizer industry requires efficient pumping, dredging, and dewatering for various operational needs. Pumping systems transport raw materials and fluids crucial for fertilizer production, optimizing manufacturing efficiency and product quality. Dredging activities maintain water channels for transportation and cooling, supporting logistical operations and environmental management. Dewatering systems manage wastewater and industrial effluents, ensuring regulatory compliance and minimizing pollution. These practices support operational reliability and environmental responsibility in Zimbabwe’s fertilizer manufacturing sector.

Beverages

Efficient pumping, dredging, and dewatering are essential in Zimbabwe’s beverage industry. Pumping systems facilitate fluid transport crucial for beverage production, ensuring consistent supply and product quality. Dredging activities may be required to maintain water channels for transportation and cooling, supporting operational logistics. Dewatering systems manage wastewater, meeting environmental regulations and minimizing pollution. These practices optimize operational efficiency and environmental sustainability in Zimbabwe’s beverage manufacturing sector.

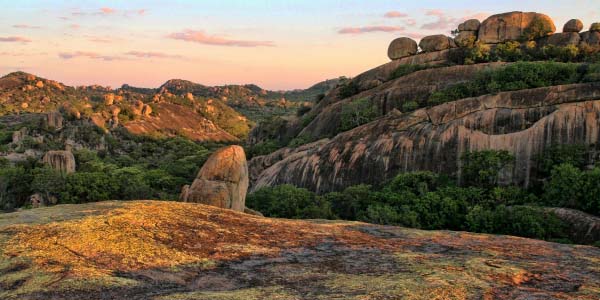

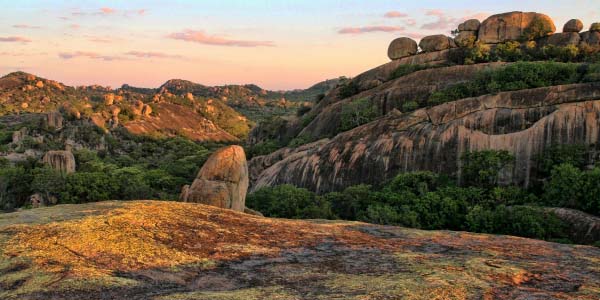

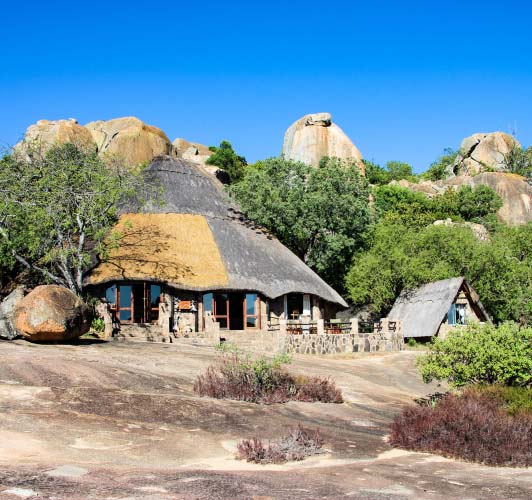

Our Presence in the Country

Conclusion

The industries of mining, steel production, wood products, cement manufacturing, chemicals, fertilizer production, and beverages in Zimbabwe rely heavily on efficient pumping and dredging projects. These essential initiatives are critical for groundwater control, ore slurry transportation, maintaining tailings dams, and managing water reservoirs crucial for wastewater and process fluid management. By implementing robust pumping and dredging projects, Zimbabwe optimizes industrial processes, enhances productivity, and ensures environmental sustainability and regulatory compliance. Continued investment in these projects is imperative for sustaining operational reliability, promoting economic growth, and securing Zimbabwe’s position as a competitive player in global markets. Emphasizing the importance of pumping and dredging projects in Zimbabwe underscores the nation’s commitment to responsible resource management and industrial development in the years ahead.