Slurry pumps play an important part in a variety of industries, including mining, oil and gas, and heavy manufacturing. These pumps are specifically built to handle abrasive, viscous, or corrosive fluids, making them critical to operational efficiency. However, given the demanding nature of these conditions, slurry pump services are necessary to ensure their continuous operation and lifespan.

A well-maintained slurry pump can run at maximum efficiency, delivering ideal flow rates while consuming the least amount of energy. In contrast, failing to properly maintain pumps can result in increased wear, unexpected breakdowns, and substantial downtime, all of which can greatly increase operating expenses. Unplanned downtime, in particular, may be exceedingly costly, disrupting production schedules, raising maintenance costs, and possibly harming essential components of infrastructure.

This makes slurry pump services not just a matter of convenience but a necessity for minimizing the risk of failure and ensuring consistent, reliable performance in high-stakes environments. Routine maintenance, repairs, and upgrades through professional slurry pumping service providers can extend the life of the pump, improving overall system efficiency and reducing the likelihood of costly repairs in the future.

This blog is designed for procurement heads, engineering managers, project contractors, government buyers (including those in the military, naval, and municipal sectors), and other decision-makers who require reliable and cost-effective maintenance strategies. Understanding how expert slurry pump services and specialized service for submersible slurry pumps help prolong equipment life and ensure consistent operational performance is key to optimizing asset value and securing high ROI.

1. Key Maintenance Practices for Slurry Pumps

Effective slurry pump services go beyond simple repairs; they involve a strategic combination of inspections, lubrication, alignment, cleaning, and component replacement. These maintenance practices are essential to minimize downtime, improve efficiency, and extend the service life of both standard and submersible slurry pumps used across industries like mining, oil & gas, power generation, and wastewater management.

Routine Inspections

Routine inspections form the foundation of any successful slurry pumping service. Regular visual and mechanical checks allow maintenance teams to identify early warning signs of wear, leakage, or performance degradation.

For service for submersible slurry pumps, inspections are even more critical. These pumps operate submerged in harsh and debris-filled environments, increasing the risk of seal failure and clogging. Specialized underwater inspections and non-intrusive testing methods ensure reliability without frequent disassembly.

Lubrication and Seal Management

Proper lubrication is one of the most essential components of professional slurry pump services. Bearings, mechanical seals, and gland packings must be regularly lubricated using the manufacturer’s recommended grade and schedule. Insufficient lubrication can lead to overheating, increased wear, and early bearing failure.

Proper maintenance of packing glands and mechanical seals is crucial to prevent slurry leakage into the motor housing or bearing assembly. This is particularly vital for submersible slurry pumps, as water ingress can quickly lead to motor failure.

Reliable slurry pumping service providers include lubrication checks and seal integrity testing as part of standard maintenance protocols, reducing the risk of unexpected shutdowns.

Component Wear Monitoring and Replacement

Using high-wear materials such as rubber or hardened metal alloys helps extend component life, but no part lasts forever. Trusted slurry pump services use OEM or high-grade aftermarket parts to ensure compatibility and optimal performance.

Shaft and Coupling Alignment

Proper alignment between pump and motor shafts is vital to reduce vibration, minimize energy consumption, and prevent premature bearing wear. Misalignment can cause cascading failures across the drive system, including seal damage and excessive noise.

Quality slurry pump services often employ laser alignment tools during installation and scheduled maintenance. Realignment is critical after component replacement, motor repair, or transport of the pump unit.

When servicing submersible slurry pumps, internal shaft alignment is crucial. Additionally, the motor-pump integration requires testing to guarantee efficient torque transmission and minimal vibration during operation.

System Flushing and Cleaning

After the operation, especially when handling thick, abrasive, or corrosive slurries, cleaning the pump system is essential. Comprehensive slurry pump services include flushing with clean water to remove residual solids and prevent hardening deposits that damage impellers or clog suction lines.

For service for submersible slurry pumps, cleaning also involves removing external debris from intake screens and ensuring no sediment accumulation restricts flow or damages the casing.

2. Ensuring Optimal Pump Performance

Monitor Vibration and Temperature Levels

Regular monitoring of vibration and temperature is a challenging task, but essential for maintaining optimal pump performance in the slurry pump. Abnormal vibrations may indicate misalignment, imbalance, or internal wear of components such as bearings, impellers, or seals. Elevated temperatures can signal inadequate lubrication, friction, or blockages.

Implementing real-time monitoring with vibration and temperature sensors helps detect early issues, reducing emergency repairs and costly downtime. For operations requiring service for submersible slurry pumps, these monitoring practices are vital due to the harsher operating conditions.

Track Operational Data

Tracking operational data such as discharge pressure, flow rates, and energy consumption is an indispensable aspect of slurry pumping service aimed at consistent pump performance. Deviations can indicate clogging, worn parts, or inefficient operation.

Real-time data tracking enables maintenance teams to respond swiftly to problems, improving performance and extending pump life.

Preventive Maintenance Scheduling

Scheduled inspections and maintenance offered by slurry pump services help detect minor issues before they escalate. A preventive plan covers daily, monthly, quarterly, and annual checks, focusing on bearings, seals, impellers, and casing.

Partnering with an experienced slurry pumping service provider ensures pumps stay in optimal condition, reducing downtime and repair costs. This is especially crucial for service for submersible slurry pumps, which face unique environmental challenges.

Stay Within Manufacturer Guidelines and Best Efficiency Points (BEP)

Adhering to manufacturer guidelines and operating pumps near their Best Efficiency Point (BEP) maximizes performance. Operating at or near BEP reduces energy consumption, wear, and mechanical stress.

For industries relying on slurry pump services, maintaining pumps within BEP is key to lowering energy costs and extending equipment life, particularly for service for submersible slurry pumps in submerged environments.

3. Comprehensive Maintenance Protocols

Maintenance Frequency Breakdown

A structured maintenance schedule is essential for effective slurry pump services. Without consistent upkeep, pumps suffer premature wear, reduced efficiency, and unexpected downtime.

A frequency-based protocol ensures routine and critical tasks occur at the right intervals, protecting both the pump and operations. This approach helps companies shift from reactive to preventive maintenance, improving operational continuity.

Importance of Maintenance Documentation

Accurate service records are a vital yet often overlooked part of slurry pump services. Documenting inspections, lubrication, component replacements, and performance logs is invaluable for trend analysis and root cause investigations.

Maintenance logs also assist procurement heads and engineering managers in justifying parts, contracts, or upgrades, especially when overseeing service for submersible slurry pumps, which are harder to access.

Tailoring Maintenance to Operating Conditions

Different slurry pumps face unique challenges based on their application. Pumps in abrasive mining slurries require different care than those in municipal wastewater systems or offshore platforms.

Effective slurry pump services must tailor maintenance schedules and protocols accordingly. For example, more frequent inspections for seals and liners are necessary in acidic or corrosive slurry applications. Meanwhile, service for submersible slurry pumps must account for water ingress and debris risks specific to submerged environments.

4. Best Practices for Cleaning a Slurry Pump

Step-by-Step Cleaning Procedure

Proper cleaning is a cornerstone of professional slurry pump services that directly affects pump reliability, performance, and longevity. Residual slurry can harden inside casings, impellers, and discharge lines, causing clogs, reduced efficiency, and premature wear.

Whether servicing standard slurry pumps or performing service for submersible slurry pumps, thorough cleaning maintains flow rates and prevents downtime.

Recommended cleaning steps include:

- Isolate the Pump: Disconnect power and close inlet/outlet valves to ensure safety.

- Drain Remaining Slurry: Open drain ports to remove residual slurry, preventing hardening or contamination.

- Flush with Clean Water: Use high-pressure water jets to remove fine particles from the pump housing, impeller, volute, and piping.

- Apply Compatible Cleaning Agents: Use manufacturer-approved detergents and non-abrasive tools like nylon brushes to dislodge stubborn deposits without damaging surfaces.

- Final Rinse and Inspection: Rinse thoroughly, allow drying, then inspect all components for wear, corrosion, or cracks. Replace damaged parts as part of slurry pump services.

Cleaning Frequency and Application-Specific Adjustments

For clients requiring service for submersible slurry pumps, cleaning frequency is critical. Submerged pumps accumulate external debris and sediment, so regular flushing of internal and external parts protects impellers, seals, and motor housings from damage.

Tailoring cleaning to slurry type, pump model, and duty cycle helps reduce repair costs and improve reliability.

The ROI of Proper Cleaning in Slurry Pump Services

Routine cleaning delivers long-term financial and operational benefits. Clean pumps reduce emergency shutdowns, lower replacement frequency, and run more efficiently.

When included in comprehensive slurry pumping service packages, cleaning becomes a key preventive maintenance tool protecting your capital investment, crucial in industries like oil & gas, chemical processing, and municipal infrastructure.

5. Advanced Technologies Enhancing Slurry Pump Services

In recent years, advancements in technology have transformed how slurry pump services are performed, significantly improving the efficiency, reliability, and cost-effectiveness of maintenance and repair operations. Integrating innovative tools and techniques into slurry pumping service programs helps companies maintain peak pump performance, reduce downtime, and extend equipment life, especially in demanding environments requiring service for submersible slurry pumps.

Predictive Maintenance with IoT and Smart Sensors

One of the most significant technological breakthroughs in slurry pump services is the adoption of Internet of Things (IoT) devices and smart sensors. These sensors continuously monitor critical pump parameters such as vibration, temperature, pressure, and flow rate, transmitting real-time data to centralized control systems.

For companies relying on slurry pumping service providers, these smart monitoring tools enable a shift from reactive to predictive maintenance. By analyzing sensor data, maintenance teams can detect early signs of wear or failure in pump components before catastrophic breakdowns occur.

This capability is particularly crucial for service for submersible slurry pumps, where access for manual inspections is limited and environmental conditions are harsh. Real-time alerts from sensor networks allow operators to schedule maintenance proactively, minimizing costly unplanned downtime and preventing extensive damage.

Remote Diagnostics and Virtual Inspections

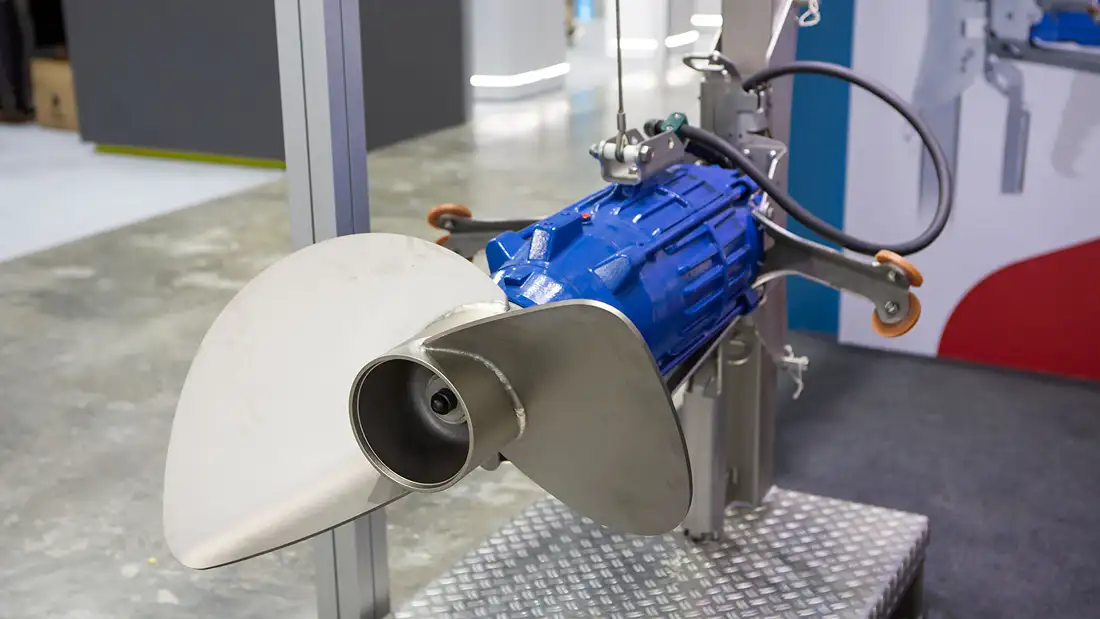

Modern slurry pump services increasingly utilize remote diagnostics and virtual inspection technologies. High-resolution cameras, drones, and remotely operated vehicles (ROVs) equipped with advanced imaging tools can access hard-to-reach locations, including submerged pump installations requiring specialized service for submersible slurry pumps.

Through virtual inspections, experts can assess pump condition, identify corrosion, seal leaks, or buildup without physically disassembling equipment. This approach saves time, reduces safety risks, and optimizes resource allocation during maintenance activities.

For companies with widespread operations or remote sites, incorporating remote diagnostics into their slurry pumping service contracts ensures consistent monitoring and expert evaluations, regardless of geographic constraints.

Advanced Materials and Coatings for Component Longevity

Innovations in materials science have enhanced the durability and performance of components used in slurry pump services. Manufacturers now offer wear-resistant alloys, composite liners, and advanced rubber compounds specifically engineered to withstand abrasive and corrosive slurry conditions.

Employing these materials during routine repairs or overhauls within a slurry pumping service significantly extends the operational lifespan of critical parts such as impellers, wear plates, and liners.

Additionally, specialized protective coatings can be applied during service for submersible slurry pumps to guard against corrosion and erosion caused by harsh underwater environments. These coatings improve seal life and reduce maintenance frequency, delivering long-term cost savings.

Automation and Robotics in Maintenance Operations

Automation technologies and robotics are playing an increasingly important role in slurry pump technology, especially in heavy industrial applications. Automated lubrication systems ensure precise and consistent application of lubricants to bearings and seals, reducing human error and extending service intervals.

Robotic arms and remote handling systems are also being deployed during service for submersible slurry pumps to perform tasks such as cleaning, seal replacement, and component alignment within confined or hazardous spaces.

By integrating robotics into slurry pumping service workflows, companies enhance worker safety, reduce maintenance time, and improve the accuracy of repair procedures.

Data Analytics and Maintenance Optimization

Big data analytics software is becoming a vital part of sophisticated slurry pump services programs. By compiling historical maintenance records, sensor data, and operational metrics, analytics platforms generate actionable insights that help optimize maintenance schedules and inventory management.

This data-driven approach enables slurry pumping service providers to predict when specific components will require replacement, avoid unnecessary downtime, and negotiate better service contracts with clients.

For operations dependent on service for submersible slurry pumps, analytics tools help fine-tune maintenance plans to the unique environmental and operational challenges these pumps face, ensuring reliable, cost-efficient service delivery.

6. Effective Troubleshooting Techniques for Slurry Pumps

Troubleshooting slurry pumps is an essential skill for maintenance teams to ensure continued operation and avoid costly downtime. Given the harsh conditions under which slurry pumps operate, issues can arise from a variety of sources, including mechanical wear, hydraulic inefficiencies, and operational errors. Developing a systematic troubleshooting approach enables timely diagnosis and efficient resolution of common problems, safeguarding equipment longevity and performance.

Identifying Common Symptoms and Causes

The first step in troubleshooting is recognizing symptoms that indicate a problem. Common signs include abnormal noise or vibration, reduced flow rate, increased power consumption, frequent seal failures, and overheating. Each symptom can have multiple underlying causes, so a thorough investigation is necessary.

For example, abnormal vibration often points to misalignment, imbalance, or worn bearings. Reduced flow rates may be caused by clogged suction lines, impeller damage, or air entrainment. Understanding the relationship between symptoms and potential causes allows technicians to narrow down the issue and focus their efforts effectively.

Systematic Diagnostic Procedures

A thorough diagnostic technique starts with a visual check of the pump and its surrounding components. Inspect for leaks, cracks, corrosion, and loose fittings. Ensure that all connections and couplings are secure. This initial stage frequently shows obvious mechanical issues or exterior damage.

Next, evaluate operating parameters such as discharge pressure, flow rate, power consumption, and temperature. Compare the results to the manufacturer’s specs and historical baseline data. Deviations can help identify particular problems, such as bearing failure due to higher power consumption or seal breaches caused by unusual discharge pressure fluctuations.

Vibration analysis using portable sensors or online monitoring systems gives extra information about the mechanical state. Unusual vibration frequencies or patterns can assist in detecting imbalance, misalignment, or resonance issues early on.

Addressing Hydraulic Problems

Hydraulic inefficiencies are a common cause of slurry pump issues. Impeller damage from abrasion or corrosion affects pumping capacity and efficiency. Worn liners and casings can lead to lower performance and more wear.

Regular examination and repair of hydraulic components prevent these problems from worsening. Check for obstructions in suction or discharge lines to troubleshoot flow abnormalities and ensure correct valve functioning. Air leaks in suction pipes and poor pump priming can induce cavitation, resulting in fast wear and damage.

Electrical and Control System Checks

Electrical faults and control system failures can also impact pump operation. Verify that the motor receives the right voltage and current and that protective devices such as overload relays and circuit breakers function properly.

Check control panels, sensors, and instrumentation for faults or calibration errors. Malfunctioning sensors or incorrect setpoints may trigger unintended pump shutdowns or erratic operation.

Implementing Corrective Actions

Once the root cause has been identified, take the corrective measures immediately. This may involve repairing or replacing worn mechanical parts, realigning shafts, cleaning or replacing hydraulic components, adjusting control settings, or troubleshooting electrical issues.

Recording the troubleshooting process and repair procedures is useful for future reference and helps to improve maintenance plans. Having a knowledge base of common issues and solutions helps to reduce resolution time and improve confidence.

Investing in Reliable Slurry Pump Services for Long-Term Performance

In demanding industries such as mining, oil & gas, wastewater treatment, and heavy manufacturing, maintaining pump efficiency through professional slurry pump services is essential. These services ensure uninterrupted, cost-effective, and regulatory-compliant operations.

By implementing best practices, including inspections, preventive maintenance, cleaning, and timely component replacement, companies can significantly reduce downtime, lower costs, and extend the lifespan of slurry pumps.

Partnering with expert slurry pumping service providers guarantees these tasks are executed with technical precision and expertise. Whether managing surface-mounted or requiring service for submersible slurry pumps, a proactive approach delivers measurable ROI, reduces emergency repairs, enhances energy efficiency, and safeguards valuable infrastructure.

For expert slurry pump services and personalized maintenance solutions, contact us today to ensure your operations run smoothly and efficiently.