Introduction

Pumping operations in remote or underwater environments present unique logistical and technical challenges. These settings often involve limited access, unstable terrain, unpredictable weather, and high concentrations of abrasive solids, all of which complicate the selection, deployment, and maintenance of pumping equipment. Traditional pump systems, such as standard centrifugal or trash pump rental, often fall short under such demanding conditions, particularly when dealing with high-solid-content fluids or submerged applications.

This is where a hydraulic slurry pump rental offers a significant operational advantage. Designed to handle dense, abrasive mixtures and operate efficiently in submerged or hard-to-reach areas, these heavy-duty systems deliver the performance and reliability that remote sites demand, without the capital expenditure or long-term commitment of ownership. Whether it’s for emergency bypass pumping, dewatering, tailings transfer, or dredging operations, renting the right slurry equipment ensures minimal downtime and maximum productivity.

Industries such as mining, oil and gas, municipal infrastructure, and military/naval operations frequently rely on slurry pump rental solutions to meet mission-critical objectives. From remote tailings ponds and offshore platforms to flooded urban infrastructure and defense-related water management systems, the flexibility and rugged performance of hydraulic slurry pumps make them indispensable in complex environments.

Understanding Slurry Pumping in Harsh Environments

Remote and underwater pumping environments are rarely forgiving. These settings often include harsh physical conditions, muddy terrain, submerged assets, highly abrasive materials, and limited infrastructure support. The choice of pumping equipment directly impacts the reliability, efficiency, and safety of operations in such locations.

Standard water pumps or trash pump rental may suffice for moving clear water or minimally contaminated liquids, but they are not engineered to handle the abrasive, solid-laden slurries typical of mining sites, dredging zones, or dewatering applications. In contrast, a slurry pump rental, and more specifically, a hydraulic slurry pump rental, is designed from the ground up to excel in such environments.

In harsh conditions, equipment failure can lead to delays, environmental compliance issues, and elevated operational costs. Leveraging a hydraulic slurry pump rental provides the performance reliability needed to maintain uptime without the long-term maintenance burden associated with pump ownership. For engineering managers, procurement heads, and contractors working in remote or extreme settings, selecting the right pump is not just a technical decision; it’s a strategic one.

Slurry Pump vs. Trash Pump: What’s the Right Tool?

Choosing the right pump for a remote or underwater project is critical to maintaining operational efficiency and avoiding costly downtime. Two common options often considered are slurry pump rental and trash pump rental. While they may appear similar in function, the differences in design, performance, and application suitability are significant, especially in rugged or high-solids environments.

A trash pump rental is typically used for moving water mixed with light debris, such as leaves, sticks, or small suspended solids, making it suitable for general-purpose dewatering in construction, agriculture, or municipal flood response. Trash pumps are engineered for flow over solids but are limited in handling abrasive materials or slurries with high solid content. Over time, their lighter-duty construction can lead to premature wear and increased maintenance when pushed beyond their intended use.

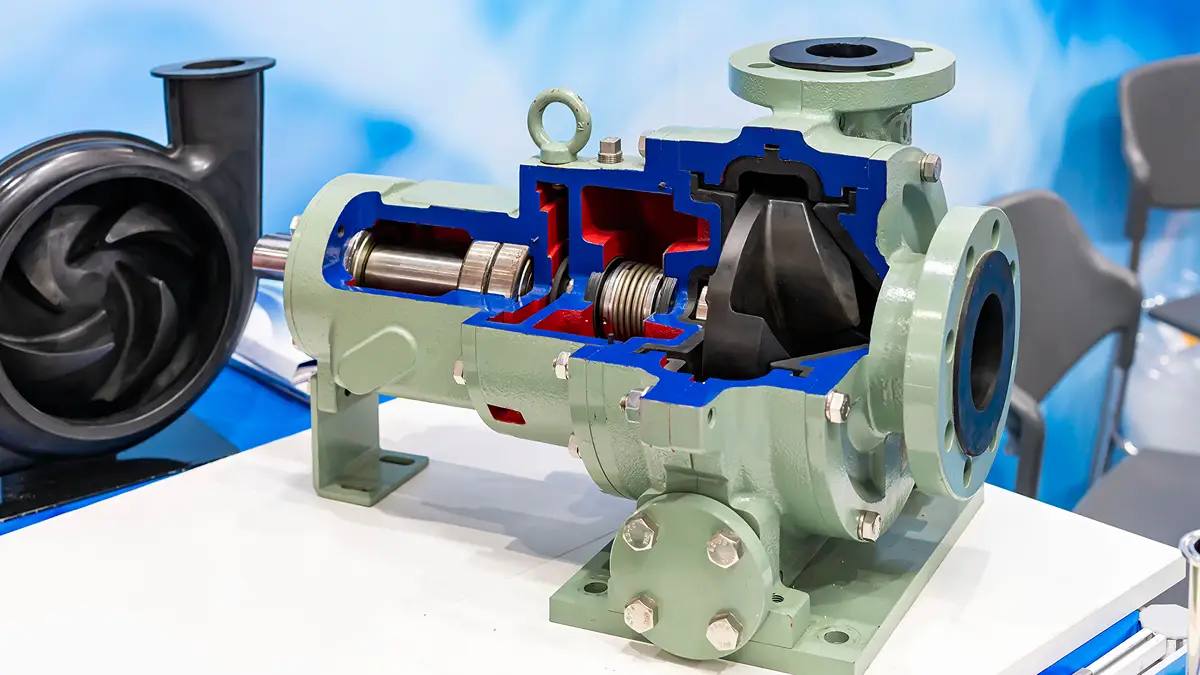

In contrast, a slurry pump rental, particularly a hydraulic slurry pump rental, is designed to transport viscous, abrasive mixtures that would quickly degrade standard pumps. These systems feature heavy-duty materials, high-chrome or rubber-lined components, and open impeller designs that resist clogging and minimize wear. Their hydraulic drive systems make them ideal for remote or underwater applications where electrical access is limited or impractical.

When dealing with mining tailings, drilling muds, dredged sediments, or sludge-heavy wastewater, the capabilities of a hydraulic slurry pump rental far exceed those of a traditional trash pump. These pumps provide the high solids handling capacity, continuous-duty performance, and rugged reliability needed to meet the demands of heavy industry and infrastructure projects.

For decision-makers in mining, oil and gas, municipal operations, or military logistics, selecting between a trash pump rental and a slurry pump rental is more than a technical detail—it’s a strategic move that impacts uptime, cost control, and overall project success.

How Hydraulic Slurry Pump Rental Overcomes Remote Site Limitations

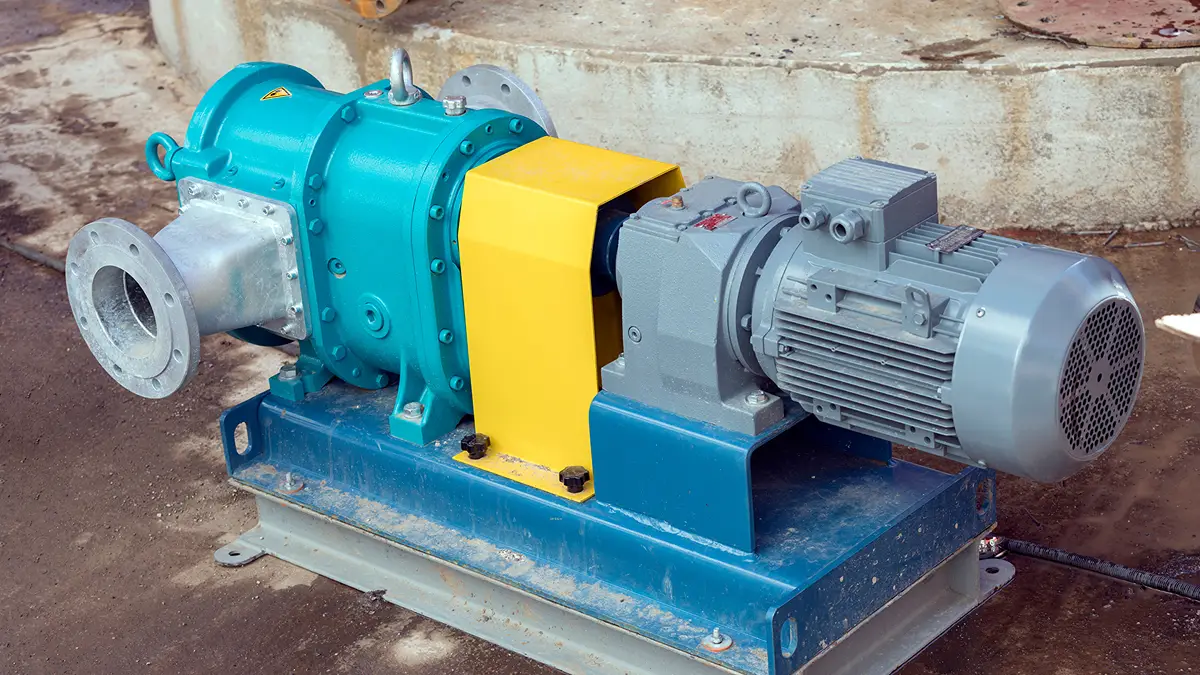

Remote and underwater job sites, such as mine pits, offshore platforms, flooded infrastructure, or dredging zones, pose a series of logistical and technical obstacles. Limited road access, unstable terrain, electrical unavailability, and harsh environmental conditions demand equipment that is not only reliable but also adaptable. In such settings, a hydraulic slurry pump rental provides a practical and performance-driven solution.

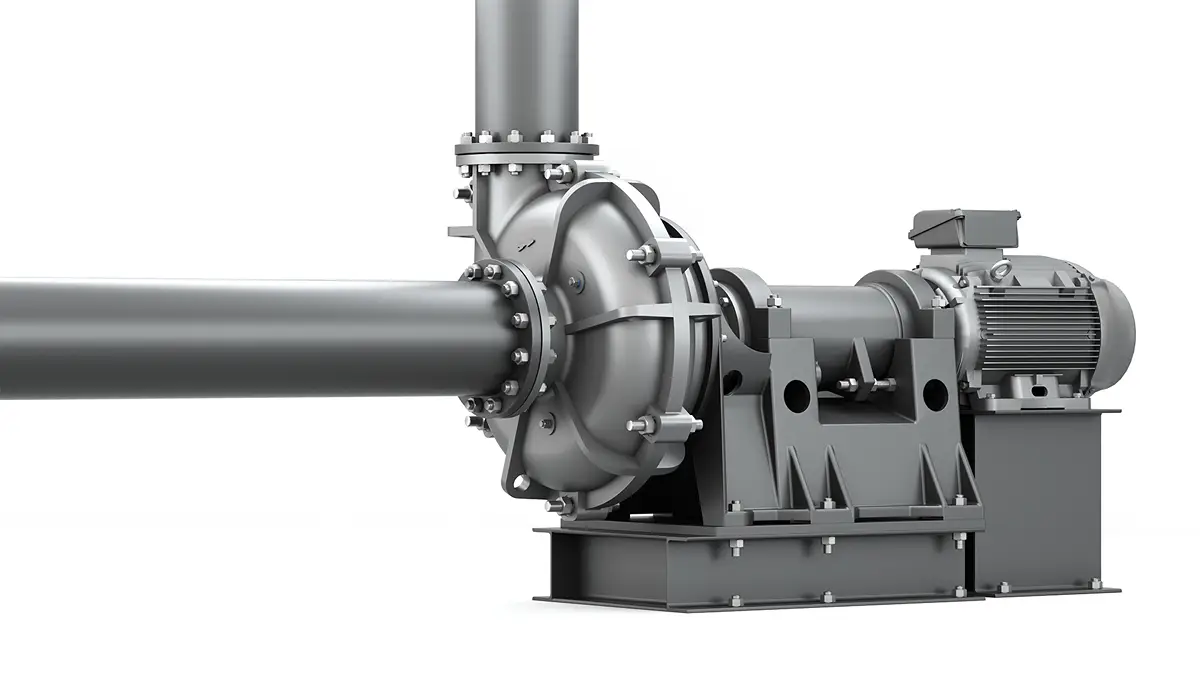

Unlike electric pumps or a conventional trash pump rental, hydraulic slurry pumps are driven by portable hydraulic power packs, eliminating the need for grid power or permanent infrastructure. This mobility allows rapid deployment in off-grid locations, shallow water, or submerged conditions, making them ideal for emergency response, bypass pumping, or high-solids dredging.

A major benefit of using a hydraulic slurry pump rental is its modular design. These systems can be easily transported via truck, trailer, or barge and assembled on-site with minimal setup time. The hydraulic drive allows for flexible hose routing and control from a safe distance, particularly valuable in hazardous or inaccessible zones. Additionally, their submersible configuration eliminates the need for external priming systems, reducing operational complexity and the risk of cavitation.

Where a trash pump rental may struggle with clogging or excessive wear in abrasive conditions, a slurry pump rental excels. Built to handle thick, heavy mixtures laden with rocks, silt, and industrial byproducts, hydraulic slurry pumps maintain flow and pressure without frequent breakdowns or manual intervention. This reliability is critical in mining, oil and gas, and municipal sectors where downtime is not an option and every hour of delay can carry significant cost.

For engineering teams and project managers working in environments where infrastructure is sparse and material demands are high, choosing a hydraulic slurry pump rental ensures robust performance without committing to the long-term expense and maintenance of ownership. It’s a strategic tool that balances flexibility, durability, and total project efficiency.

Underwater Pumping Applications: Case Examples

Underwater pumping projects are among the most complex and resource-intensive operations across industrial sectors. Whether the objective is dredging, dewatering, sediment removal, or infrastructure maintenance, the right pump must withstand not only submersion but also high-solid content and unpredictable field conditions. This is where a hydraulic slurry pump rental delivers unmatched value, offering powerful, durable performance without the capital outlay of ownership.

Military and Naval Operations

In military shipyards and naval bases, maintenance of submerged assets, such as hull cleaning, dry dock sediment removal, or underwater infrastructure repair, requires pumps that can be deployed quickly, work underwater, and handle heavy debris. A hydraulic slurry pump rental meets these demands with its submersible capability and ability to move dense slurries with high concentrations of silt, rust, or barnacle buildup. Unlike a trash pump rental, which would clog or fail under similar conditions, hydraulic slurry pumps maintain flow consistency and uptime in mission-critical settings.

Municipal Infrastructure Projects

Municipalities often face urgent underwater pumping needs during stormwater surges, sewer overflows, or infrastructure failures. In these scenarios, time and mobility are critical. With a slurry pump rental, municipalities can deploy submersible systems into flooded vaults, retention basins, or collapsed pipelines without the need for complex rigging or priming systems. The hydraulic drive units can be positioned remotely, ensuring safe and effective pumping in hazardous or confined spaces. These capabilities go far beyond what traditional trash pump rental can handle, particularly when debris and sludge loads are excessive.

Oil and Gas: Subsea and Offshore Applications

On offshore rigs and subsea installations, underwater pumping tasks may include drilling mud recovery, tank cleaning, and pipeline maintenance. A hydraulic slurry pump rental is ideally suited for these environments, where electrical power is often restricted and fluid characteristics are highly abrasive. These pumps can operate fully submerged, delivering the high torque and solids-handling capacity needed for demanding offshore operations. Their durability and compact modularity also make them easier to transport via supply vessels or helicopters, reducing logistics overhead and response time.

From harbor dredging to subsea dewatering and underwater excavation, hydraulic slurry pump rental is a proven solution for industries that need reliable, high-performance pumping without compromise. In contrast to a trash pump rental, which is limited in both depth and material handling, a slurry pump rental provides the flexibility and ruggedness essential for challenging underwater environments.

Performance Advantages of Hydraulic Slurry Pumps

In environments where abrasive materials, high-solid content, and extreme operating conditions are the norm, performance and reliability are non-negotiable. A hydraulic slurry pump rental offers a distinct advantage over standard pumping options by combining industrial-grade durability with application-specific engineering that directly supports uptime, efficiency, and cost control.

Built for Abrasive and High-Solids Applications

Unlike a standard trash pump rental, which is typically designed for handling water with occasional debris, a slurry pump rental is specifically engineered to move mixtures with a high concentration of solids, such as sand, gravel, ore, or industrial sludge. Hydraulic slurry pumps feature wear-resistant materials like high-chrome alloys and heavy-duty liners that resist corrosion and erosion even under constant exposure to aggressive media.

Submersible Operation and Remote Power

A major performance advantage of choosing a hydraulic slurry pump rental is its ability to operate submerged. Powered by hydraulic systems instead of direct electricity, these pumps are ideal for underwater tasks in mining pits, flood zones, or offshore installations where electrical connections are impractical or unsafe. This capability also eliminates the need for complex priming, improves safety, and allows for greater flexibility in deployment.

Reduced Downtime and Lower Maintenance Costs

Because of their rugged design, hydraulic slurry pump rental typically experiences fewer failures due to wear, clogging, or mechanical stress. For procurement managers and project engineers, this translates to fewer service calls, lower maintenance budgets, and a more predictable operating schedule. The ability to quickly replace or upgrade a rented unit, without long procurement lead times, also supports continuity during critical project phases.

While trash pump rental may seem like a cost-effective choice for temporary projects, it often fails under heavy load or extended use in abrasive environments, leading to increased maintenance and premature failure. In contrast, a properly sized slurry pump rental delivers consistent throughput and lower total cost of operation over the project lifecycle.

Whether for industrial dredging, mining slurry transport, municipal bypass pumping, or offshore dewatering, a hydraulic slurry pump rental offers unmatched performance advantages that directly contribute to operational reliability, safety, and efficiency.

Common Failure Modes And How Rentals Mitigate the Risk

Slurry pumping systems operate in some of the harshest environments imaginable—handling abrasive, corrosive, and dense mixtures that can accelerate mechanical wear and lead to costly failures. Understanding the common failure modes of these pumps is essential for selecting the right solution. Opting for a hydraulic slurry pump rental not only provides access to specialized equipment but also offers built-in risk mitigation through service support, modern fleet availability, and reduced maintenance burdens.

Typical Failure Modes in Slurry and Trash Pumps

- Blockages and Clogging: One of the most frequent issues in both trash pump rental and slurry pump rental is clogging due to oversized solids or material buildup in the suction or discharge lines. Trash pumps, in particular, are prone to blockages when used beyond their design limitations, especially in heavy sludge or sediment-rich conditions.

- Excessive Wear and Abrasion: The constant exposure to abrasive solids such as sand, gravel, or ore leads to rapid degradation of impellers, liners, and volutes. While a slurry pump rental is built to withstand this wear, failure to monitor wear components can still result in reduced flow rates or leakage over time.

- Vibration and Bearing Wear: High vibration, often caused by imbalance, misalignment, or uneven wear, can result in bearing failures, motor damage, or even structural fatigue. These failures are more prevalent in improperly selected or overused trash pump rentals, which are not designed for prolonged high-solids operation.

How Hydraulic Slurry Pump Rental Reduces Operational Risk

Choosing a hydraulic slurry pump rental provides an immediate performance advantage by ensuring the equipment is purpose-built for abrasive and high-solids environments. These systems are engineered with features such as wear-resistant materials, open impeller designs, and robust mechanical seals, all of which reduce the frequency and severity of common failure modes.

Additionally, project teams gain access to expert configuration and sizing advice during the rental process, ensuring the selected slurry pump rental or hydraulic slurry pump rental is matched precisely to the application’s flow rate, head pressure, and solids content. This proactive approach minimizes the likelihood of underperformance or mechanical stress during operation.

In contrast, relying on a trash pump rental for tasks beyond its design scope increases the risk of breakdowns and operational inefficiency. For high-stakes projects, especially in remote or underwater settings, this can translate into missed deadlines, environmental violations, or inflated costs.

Ultimately, integrating a hydraulic slurry pump rental into your project plan is not just about equipment access; it’s a strategic measure to manage mechanical risk, improve uptime, and protect project timelines.

ROI for Procurement and Project Leaders

For procurement heads, engineering managers, and project contractors, capital allocation must strike a balance between performance, flexibility, and long-term value. When it comes to fluid handling in challenging environments, the decision between purchasing and renting equipment has a direct impact on budget efficiency and project risk. Choosing a hydraulic slurry pump rental offers a compelling return on investment, both in financial and operational terms, especially for short- to mid-term projects with high-solid, high-abrasion demands.

Lower CapEx, Predictable OpEx

Investing in high-capacity pumping systems, particularly those capable of handling abrasive slurries, requires significant capital expenditure. Ownership also introduces long-term costs tied to maintenance, storage, depreciation, and staffing. In contrast, a hydraulic slurry pump rental transforms that upfront CapEx into a manageable operational expense (OpEx), allowing decision-makers to allocate resources more flexibly across multiple projects or departments.

This model is especially beneficial in industries like mining, oil and gas, or municipal infrastructure, where the need for slurry pump rental may be seasonal, project-specific, or based on emergency response. By renting only when needed, organizations avoid the sunk costs of owning underutilized equipment.

Maximized Uptime and Project Continuity

A key ROI driver of hydraulic slurry pump rental is the assurance of uptime. Rental providers typically supply well-maintained, late-model pumps with factory-spec performance. When issues arise, such as wear or mechanical failure, support teams can quickly replace or service the equipment, ensuring continuity without the delays associated with in-house troubleshooting or procurement of spare parts.

Compared to relying on a trash pump rental, which may not be designed for the rigors of abrasive or high-solid applications, a slurry pump rental minimizes the risk of clogging, unplanned maintenance, and performance degradation. This reliability translates directly into faster project timelines, reduced overtime costs, and fewer disruptions to downstream operations.

Operational Flexibility and Scaling

A hydraulic slurry pump rental provides project teams with the ability to scale up or down quickly based on site demands. Whether mobilizing for a dredging operation, emergency sewer bypass, or mine pit dewatering, rental fleets allow organizations to match equipment capacity precisely to job scope, without the financial or logistical burden of owning and transporting oversized or undersized units.

Risk Mitigation and Budget Control

Owning slurry equipment introduces risk, from sudden equipment failure and replacement costs to compliance fines from downtime-related environmental impacts. With a hydraulic slurry pump rental, much of that risk is absorbed by the rental provider through service level agreements, warranties, and access to backup units.

For government buyers, defense contractors, or municipal procurement officers operating within strict budget controls and approval cycles, rentals offer a transparent and predictable cost structure. This clarity enables better project forecasting and aligns with the accountability expectations of public-sector or enterprise-level stakeholders.

In today’s capital-constrained and results-driven environment, opting for a slurry pump rental and specifically a hydraulic slurry pump rental is not just a tactical decision. It’s a strategic move that aligns performance needs with financial discipline, reduces operational risk, and improves ROI across the full life cycle of a project.

Conclusion: Strategic Use of Hydraulic Slurry Pump Rental in Demanding Environments

For projects involving high-solids content, remote access, or submerged pumping conditions, a hydraulic slurry pump rental offers a strategic and cost-effective alternative to equipment ownership. Unlike a general-purpose trash pump rental, which is suitable only for light debris and clean water applications, hydraulic slurry pumps are specifically engineered to handle abrasive slurries, submerged deployments, and high-wear environments. This makes them ideal for industries such as mining, oil and gas, municipal infrastructure, and military operations, where operational uptime and equipment resilience are critical. Choosing a slurry pump rental, particularly a hydraulic variant, allows procurement and project teams to avoid the capital expenditure of purchasing, while benefiting from modular deployment, expert support, and reduced maintenance risk. Whether facing a temporary dewatering challenge or a complex underwater pumping task, renting the right pump ensures performance, safety, and a measurable return on investment, all without the long-term liabilities of ownership.

Contact Pump & Slurry today to ensure your operation runs efficiently—no matter how remote or demanding the environment.