Monitoring Pump Vibration Levels

Routine monitoring can alert the operator to potential problems.

Vibration levels can be used to monitor bearing condition and provide an excellent diagnostic tool for preventative maintenance. Both permanently mounted accelerometers and portable sensing units can be used to track changes in the vibration signal as the equipment ages. Once baseline measurements are established under normal operating conditions, routine monitoring can alert the operator to potential problems.

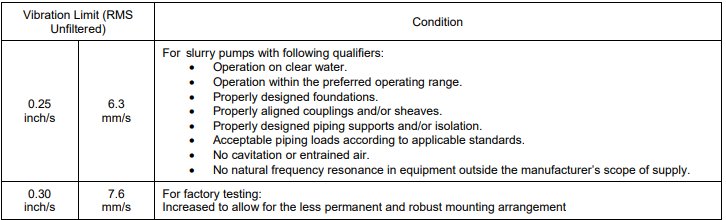

Typical baseline values

Vibration levels can be used to monitor bearing condition and provide an excellent diagnostic tool for preventative maintenance. Both permanently mounted accelerometers and portable sensing units can be used to track changes in the vibration signal as the equipment ages. Once baseline measurements are established under normal operating conditions, routine monitoring can alert the operator to potential problems.

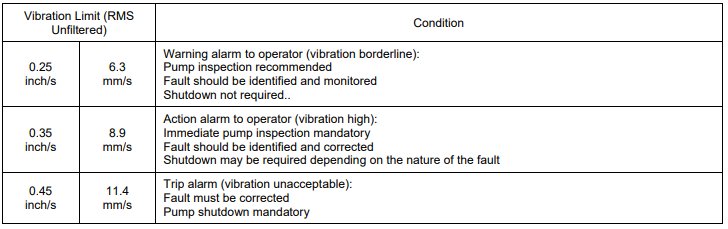

Typical set points

As with temperature, vibration readings can be used to trigger alarms or pump shut down. Setpoints may need to be adjusted according to ambient conditions created by the operating environment. For medium-duty conditions approximating the above qualifiers, the following set points would be typical.