Considerations

- Landfills

- Wet-to-dry ash handling system conversions

- Handling and disposal systems

- Closure of wet and dry ash disposal facilities

Environmental Studies and Permitting:

- Permitting

- Preliminary and detailed site investigations

- Environmental assessments

- Environmental investigations and remediation

Are There any Beneficial Uses?

- Underground and surface mine reclamation

- Coal yard base and pond liner material (roller compacted concrete)

- Leachate collection system media

- Protective soil cover systems

Ash Handling & Disposal:

- Bottom Ash Handling

- Fly Ash Handling

- Pond Retrofit/Closure

Dewatering Fly Ash for Remediation

Fly ash has properties and behaviors that present unique challenges during excavation, handling, and disposal. Fly ash material has historically been stored in ponds and is known to be unstable and sensitive to vibration when saturated. When saturated fly ash is subjected to shear strain, it densifies and expels water, resulting in a near-total loss of shear strength. In this state, the ash becomes a viscous fluid and may begin to slide or flow. This process may result in overtopping or breaching of impoundments and makes excavation and handling difficult to impossible.

Changing the water content in the ash by only a few percentage points has a dramatic effect on its behavior, allowing stable, near-vertical cuts suitable for conventional mass excavation. The increase in strength happens when a reduction in water content changes the pore pressure from slightly positive to slightly negative, imparting apparent cohesion and shear strength to the ash.

The purpose of this paper is to discuss two different methods for lowering the water content of fly ash: one where the ash was impounded in low permeability soil and one where the ash was stored directly in contact with high permeability soil. In the first instance, dewatering was conducted with an interior system of closely spaced wellpoints. In the second case, dewatering was performed using widely spaced, high capacity deep wells. In both cases, dewatering allowed for the safe and efficient handling of the ash. These projects demonstrate both the feasibility and desirability of dewatering for these types of operations.

INTRODUCTION

The two projects discussed below both required the complete removal of fly ash from existing ponds. The first project, at the Seward Generating Station in Johnstown, Pennsylvania, involved completely removing the ash and transporting it to a dry storage facility. The second project, at Daniel Electric Generating Station in Jackson County,

Mississippi, involved removal of the ash, temporary storage on-site, the lining of the pond, and replacement of the ash.

In both projects, pre-drainage of the ash using dewatering techniques common in the construction industry improved ash characteristics, project safety, and schedule. However, because of the different pond construction details and native soils at each site, the mechanism for dewatering differed for each pond.

DEWATERING IN A LINED POND

The first project was a pilot dewatering test at the Pennsylvania Electric Company’s Seward Generating Station in Johnstown, Pennsylvania.

The project was extensively documented in a 1985 report published by the Electric Power Research Institute.1 The station had been in operation since the 1920s. Until 1980, both bottom ash and fly ash were randomly deposited via slurry in storage ponds. Two ponds were used at this plant; when the first pond was full, ash deposition would switch to the second pond and the first pond would be mucked out. The ash would then be transported and deposited at a final disposal site.

After the closure of the storage ponds in 1980, the State of Pennsylvania required that the ponds be emptied and returned to the original grade. This presented two problems to the plant owner: 1) because of the low angle of repose of the near-liquid wet ash, the final disposal site did not have the capacity to store all of the ash in the ponds unless it

was pre-drained, and 2) the state required the project to be completed in under two years, requiring a relatively rapid method of pre-draining.

At the time of the project, Ash Pond 1 only contained approximately 1.2 m of ash. Therefore, it was decided to remove that ash without dewatering as it was thought that the benefits of pre-drainage would not be worth the cost for such a thin layer. Ash Pond 2, however, contained between 2.1 and 3.7 m of ash and the plant owner decided to use dewatering techniques for pre-drainage.

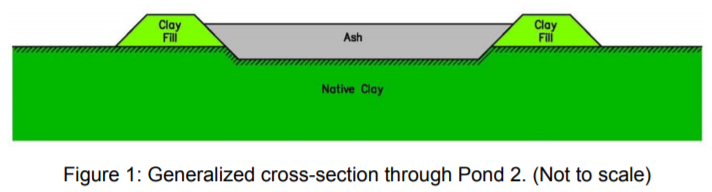

Ash Pond 2 had approximate dimensions of 122 m by 183 m and was constructed on an impermeable native clay layer with a perimeter clay fill dike (Figure 1).

Test pits dug in the ash prior to installation of any drainage devices showed a relatively stable crust approximately 1 to 1.2 m thick underlain by a zone of flowing ash that would fill a test pit as quickly as the pit could be excavated. Phreatic levels in existing observation wells in the ash were 0.30 to 0.60 m below the top of the flowing ash zone.

INITIAL TEST

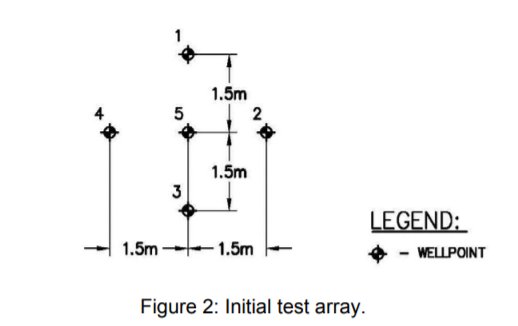

The specialty contractor retained by the Owner put in an initial array of five wellpoints (Figure 2) which individually yielded between 1 and 1.25 L/min.

The first test performed involved pumping on wellpoint #3 for 35 minutes using a centrifugal pump. The flow rate for the test was 1 L/min and the maximum drawdowns observed at a distance of 1.5 and 3 m from the test wellpoint were 0.35 and 0.20 m respectively.

The second test performed using this array involved pumping on wellpoint #2 for 310 minutes using an eductor. The flow rate for the test was 1 L/min and the maximum drawdowns observed at a distance of 1.5 and 2.1 m from the test wellpoint were 0.40 and 0.36 m respectively.

Both wellpoint and eductor systems are capable of pumping the well yields observed during the test. However, eductor systems require installation of two pipes (supply and return) while wellpoint systems require only one pipe (vacuum header). Given the similar results from the two tests and the relative simplicity of implementing a wellpoint system versus an eductor system, it was decided to move ahead with a more comprehensive wellpoint test.

SECOND TEST

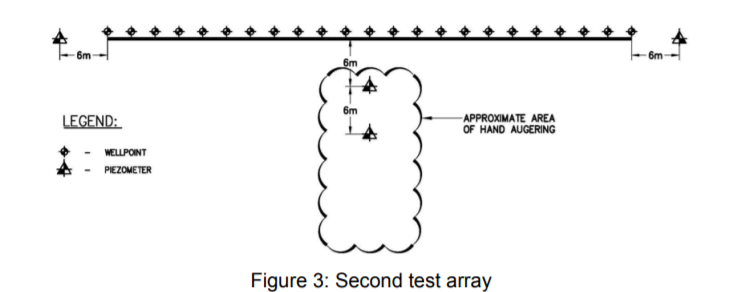

The second test array consisted of a line of 23 wellpoints (some installed in bottom ash and some in fly ash) spaced approximately 3 m apart, with piezometers installed at various distances and positions relative to the line as shown in Figure 3 below.

Over the course of a nearly 11-day pump test with all 23 wellpoints pumping, the array’s flow rate dropped from an initial value of 57 L/min to a final value of 13 L/min Drawdowns of over 0.60 m were observed at the end of the test in three of the four piezometers.

Hand auguring was conducted up to 30 m away from the wellpoint line in order to observe actual conditions in the pond just before turning off the wellpoints. Similar to the pre-pumping condition, a 1 to 1.2 m thick stable crust was encountered. This time, however, there was an approximate 0.9 m thick zone of thixotropic material beneath the stable layer. This material would tolerate the digging action but flow when subject to vibration. Below this zone the ash remained in a flowing condition.

The hand auguring revealed that longer-term pumping could increase the thickness of the excavatable zone (as compared to pre-pumping conditions) and that the thickness increased closer to the wellpoint line. This improvement in ash characteristics extended for a distance of approximately 12 m from the wellpoint line. Test pits dug near the perimeter dike also revealed poor conditions immediately adjacent to the dike even when pumping nearby. However, it was theorized that poorly controlled runoff from the dike could have been a contributing factor to this phenomenon.

Values of bulk hydraulic conductivity calculated from the pump test for the ash were on the order of 10-2 cm/s. This value is much greater than the values typically assumed for fly ash and is likely due to the co-mingling and layering of coarser bottom ash with the relatively fine fly ash.

FINAL SYSTEM DESIGN, RESULTS & CONCLUSIONS

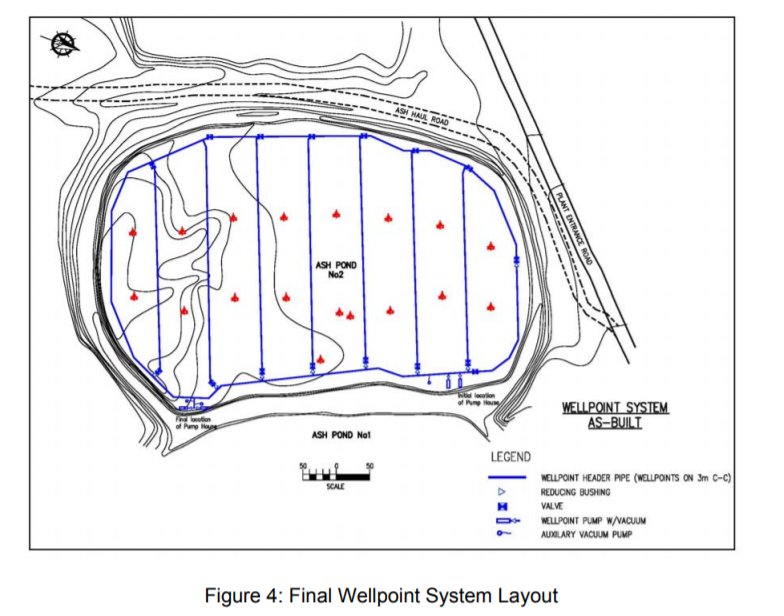

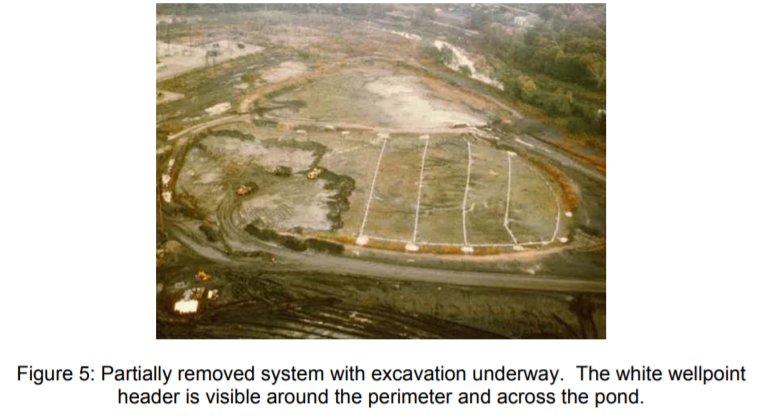

Based on the foregoing test data, the final design consisted of lines of wellpoints across the pond with 3 m between wellpoints and 24 m between wellpoint lines. The 24 m spacing was based on the observation that the ash was improved up to 12 m away from the wellpoint line during testing. This system was supplemented with a perimeter ring of wellpoints in order to address the relatively unstable conditions observed at the dike.

Piezometers were installed between the wellpoint lines in order to monitor groundwater levels and inform tuning and operation of the system. A sketch of the system is shown in Figure 4 below.

The system was installed with valves in order to allow removal of one section of the system without shutting down the remainder. This maximized pumping time by allowing the excavation contractor to begin operations in the portion of the pond thought to contain more of the free-draining bottom ash, thereby affording more pumping time in the relatively poorly draining fly ash.

The system was installed and activated in segments with approximately one week between activation of the first segment and activation of the entire system. The entire system pumped for roughly one month prior to commencement of excavation of the ash, which lasted for five weeks.

The system flow rate varied as the wellpoints were activated and deactivated incrementally. However, in general the flow rate started at approximately 150 L/min and decreased to 38 L/min within five days. After two months of pumping, the entire system

flow was below 19 L/min. It was estimated that approximately 1.52 x 106 L of water was pumped from the pond in total.

The thickness of unstable ash varied throughout the pond but in general less than 30 cm of running ash was encountered during removal. Localized low points in the bottom of the pond resulted in trapped water and the attendant degradation in ash stability. The project was successful in that dewatering of the ash greatly improved its shear strength and allowed for rapid mass excavation with conventional rubber tire equipment (Figures 6a, 6b, 6c).

In situ geotechnical testing and sampling both before and during pumping also yielded relevant information including:

- Two soil moisture gauges installed at depths of 1.2 and 1.7 m respectively showed increasing soil suction (i.e. negative pore pressure) when compared to concurrently decreasing water levels in adjacent piezometers.

- The density of the ash prior to pumping was not significantly different from that measured in post-pumping samples.

- A settlement monitoring point installed near the center of the ash pond indicated that no settlement occurred during or after drawdown.

- Hydraulic conductivity as determined from in situ pump tests was significantly higher than published values.

Conclusions drawn by the project team include:

- The apparent increase in shear strength observed during excavation could not have been due to densification or consolidation. Ash density did not increase after pumping and no consolidation settlement was observed. The increase in strength appears to be due to increasing negative pore pressure as the water in the pond is drawn down.

- In situ measurement of hydraulic conductivity may yield results significantly different from typical published values. Actual hydraulic conductivity will depend on the relative proportions of fly ash to bottom ash and the method of deposition.

- The effectiveness of the dewatering was enhanced by the intensity of the dewatering effort (i.e. closely spaced wellpoints throughout the pond). The application of vacuum also likely played a role in lowering pore pressure but this effect was not quantified.

PLANT DANIEL: DEWATERING WITH A NATURAL UNDERDRAIN

Daniel Electric Generating Plant, owned by Southern Company Services Inc. is located in Jackson County, Mississippi. The project involved completely removing the ash from a holding pond, temporarily storing it on site, installing a liner in the newly emptied pond

and replacing the ash. The pond was in the shape of a right angle triangle with side dimensions of approximately 480 m, 540 m and 300 m.

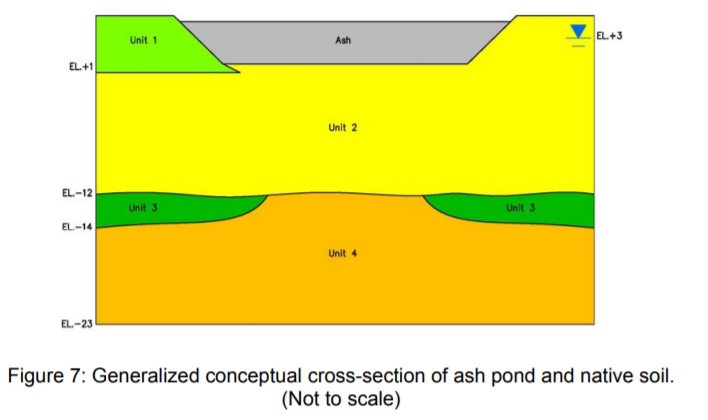

Geotechnical exploration at the site identified four native soil units, as shown in Figure 7:

Unit 1: A surficial layer of sandy to silty clay extending to a depth of approximately 9 m in some locations. This unit was discontinuous around the site.

Unit 2: A layer of slightly clayey to slightly silty, fine to medium sands extending from elevation 0 to elevation -12.2.

Unit 3: A discontinuous layer of medium gray silty to sandy clay generally encountered between elevations -13.7 and -15.2, with a thickness of between 0.8 and 2.9 m.

Unit 4: A medium sand and gravel layer between roughly elevations -15.2 and -22.9 (the maximum depth of exploration).

Groundwater was encountered between elevations 2.4 and 3.0 and exploratory holes in the pond revealed the bottom of the ash to be between elevations 0.6 and 0.9.

It was determined that since the natural groundwater elevation was above the bottom of the pond, depressurization and dewatering of the Unit 2 sand would be necessary in order to complete the project. Lowering the phreatic surface in Unit 2 would have the added benefit of inducing drainage of the ash downward into the native soil.

AQUIFER PUMPING TESTS

A specialty dewatering contractor designed and conducted several full-scale aquifer pumping tests early in the project to evaluate the aquifer parameters, fly ash permeability, communication between the aquifer and the ash, and the communication between the aquifer and the surrounding open water bodies.

An array of test wells was installed with one well screened in Unit 2 only and two wells screened in both Units 2 and 4. One of the dual screen wells was found to be low yielding and was subsequently abandoned and not used for testing.

A series of step and constant rate pumping tests revealed that the Units 2 and 4 aquifers had transmissivities of 500 and 550 m2/day respectively. These transmissivities are high relative to the thicknesses of the soil layer and indicated that the native soil was amenable to dewatering. The tests also proved that wells screened only in Unit 2 and wells screened in both Units 2 and 4 could sustainably yield 380 and 1,400 L/min respectively.

Additional testing of the ash directly indicated that it was very drainable. A single wellpoint installed 3.6 m in to the ash yielded 230 L/min and produced virtually no drawdown in an observation point 1.5 m away. This was taken as an indication that there would be good hydraulic communication between the ash and the native sands during full scale pumping.

Although strictly speaking, dewatering of only Unit 2 (as opposed to Units 2 and 4) was necessary for the project, the pumping test results, along with the fact that the Unit 3 clay was discontinuous across the site, led the project team to conclude that lowering the groundwater in Unit 4 would also be necessary to prevent it from acting as a source of recharge to Unit 2.

FINAL SYSTEM DESIGN, RESULTS & CONCLUSIONS

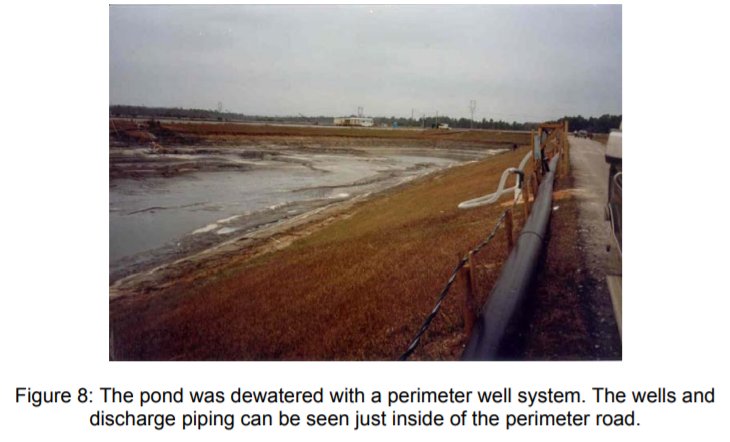

Based on the pumping test results, the design team proposed a system of 15 wells screened in Units 2 and 4 around the pond’s perimeter (Figure 8). The intent of the wells was to lower the groundwater in the Unit 2 aquifer to elevation -1.2 or lower to allow for excavation of the ash and installation of the liner.

Given the favorable results observed in the test wellpoint installed in the ash, the specialty dewatering contractor also proposed a series of ten shallow wells jetted through the ash and 3 m into the underlying Unit 2 sand (Figure 9). These wells would shorten the flow path for water draining from the ash to the sand and would also provide additional pumping capacity to aid in dewatering Unit 2.

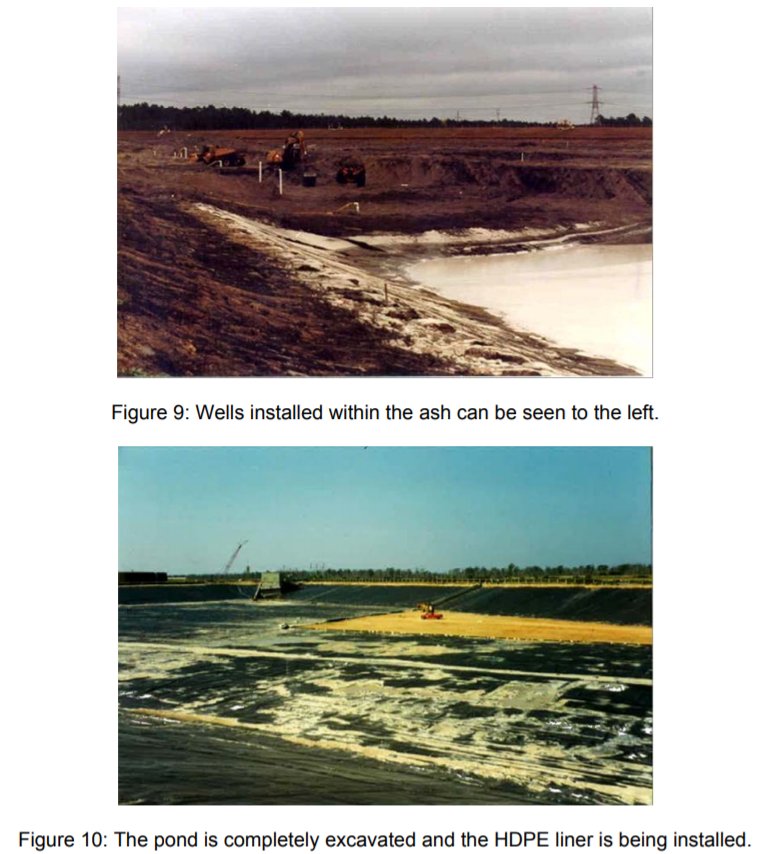

The system pumped 17,000 L/min for over a year during ash excavation, liner placement and ash replacement and successfully held groundwater below target levels for the entire project (Figure 10).

The ash was a highly stratified mix of bottom ash and fly ash with a relatively high horizontal permeability. By fully dewatering the underlying aquifer via a perimeter deep well system combined with pumping from the interior well system in the ash, the excavation proceeded safely and efficiently. Residual groundwater and surface water was handled by locally placed sumps and trenches.

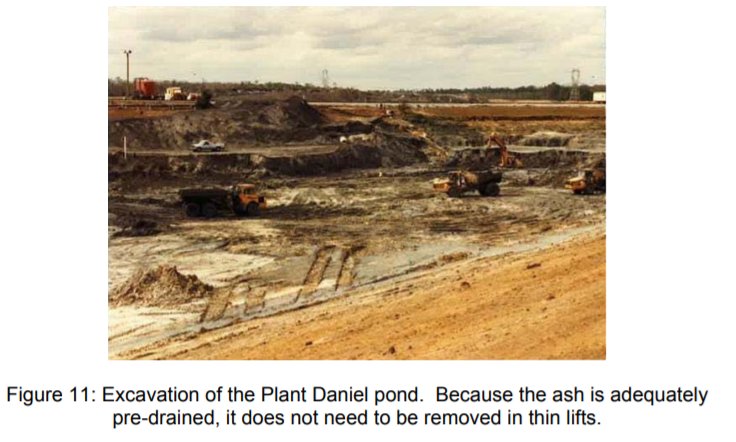

Similar to the results of the Seward Generating Station project, once the ash was drained, its excavation characteristics improved markedly. With pre-drainage the ash was able to be excavated in tall vertical lifts (Figure 11) and transported and stored dry during pond lining. This approach allowed for faster excavation and a much smaller storage footprint than if the ash had been excavated wet.

GENERAL CONCLUSIONS

The two case studies discussed above-involved ash ponds in very different geological settings. For both projects, success was dictated by a thorough understanding of the soil conditions, adequate testing of the ash’s hydraulic characteristics, and the design and implementation of dewatering systems by experienced practitioners.

Ash properties may vary greatly depending on the method of deposition and the relative proportions of fly ash and bottom ash (i.e. the layering and overall particle size distribution of the ash). Therefore, it is imperative to obtain good in situ hydraulic performance data prior to the final dewatering system design.

Furthermore, both projects show that although ash may be difficult to work within a saturated state, it is possible to radically improve its handling properties with adequate pre-drainage. This makes dewatering and excavating a suitable technique for projects with constrained schedules (more rapid excavation is possible with pre-drained ash), where it is desirable to improve the transport and storage characteristics of the ash or where positive visual confirmation that 100% of ash has been removed from the pond is required.

REFERENCES

[1] Electric Power Research Institute, Dewatering to Stabilize Fly Ash Disposal Ponds, 1985