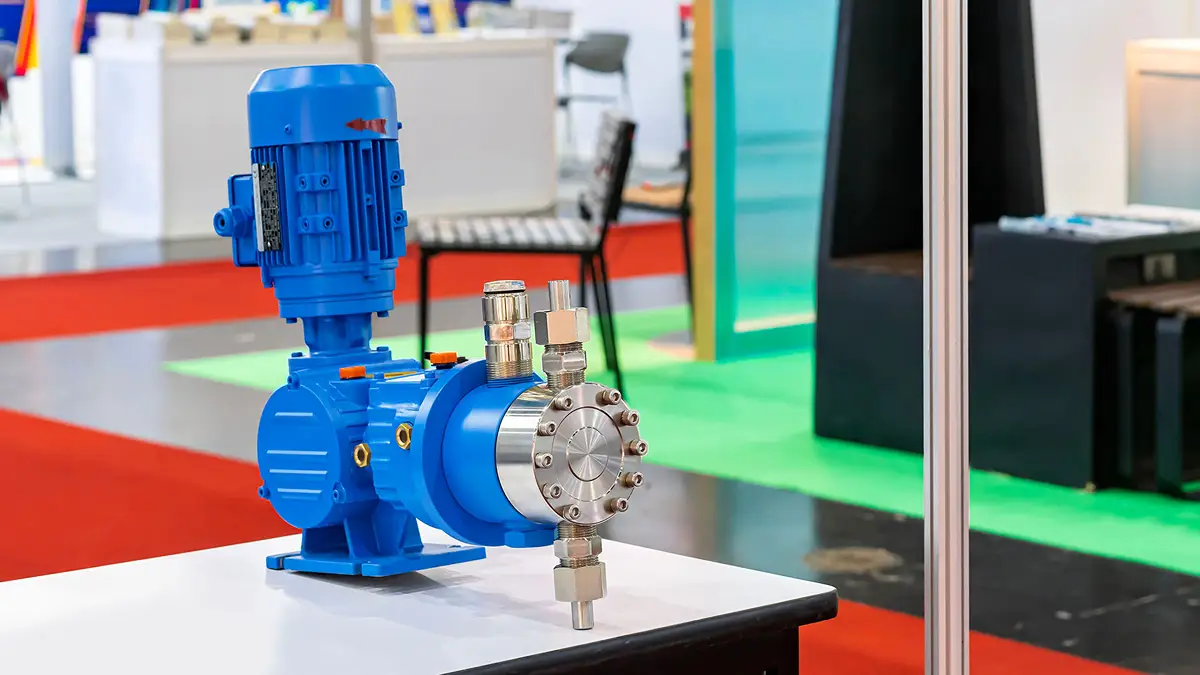

Hydraulic diaphragm pumps are essential equipment in industries that require reliable and efficient fluid handling, especially in harsh environments. These pumps use a diaphragm to create positive displacement, ensuring a continuous flow of liquid while minimizing pulsation. Their unique design makes them well-suited for applications where handling abrasive, viscous, or chemically aggressive fluids is a must. Hydraulic diaphragm pumps are commonly used in sectors such as mining, oil and gas, wastewater treatment, and municipal services due to their ability to operate in extreme conditions with minimal maintenance. In addition, hydraulic driven diaphragm pumps offer robust solutions for applications requiring consistent pressure and high flow rates, such as hydraulic dredging pumps used in dredging and sludge management.

The performance and longevity of hydraulic diaphragm pumps depend heavily on the materials selected for their components. From the diaphragm to the casing, seals, and valves, the choice of material directly influences the pump’s ability to withstand wear, resist corrosion, and handle extreme operational stresses. Whether it’s for handling slurry in mining or pumping chemicals in industrial plants, the right materials ensure that the pump can operate effectively over extended periods, even in the most demanding conditions.

This section is aimed at procurement heads, engineering managers, and project contractors in industries that rely on hydraulic diaphragm pumps for critical operations.

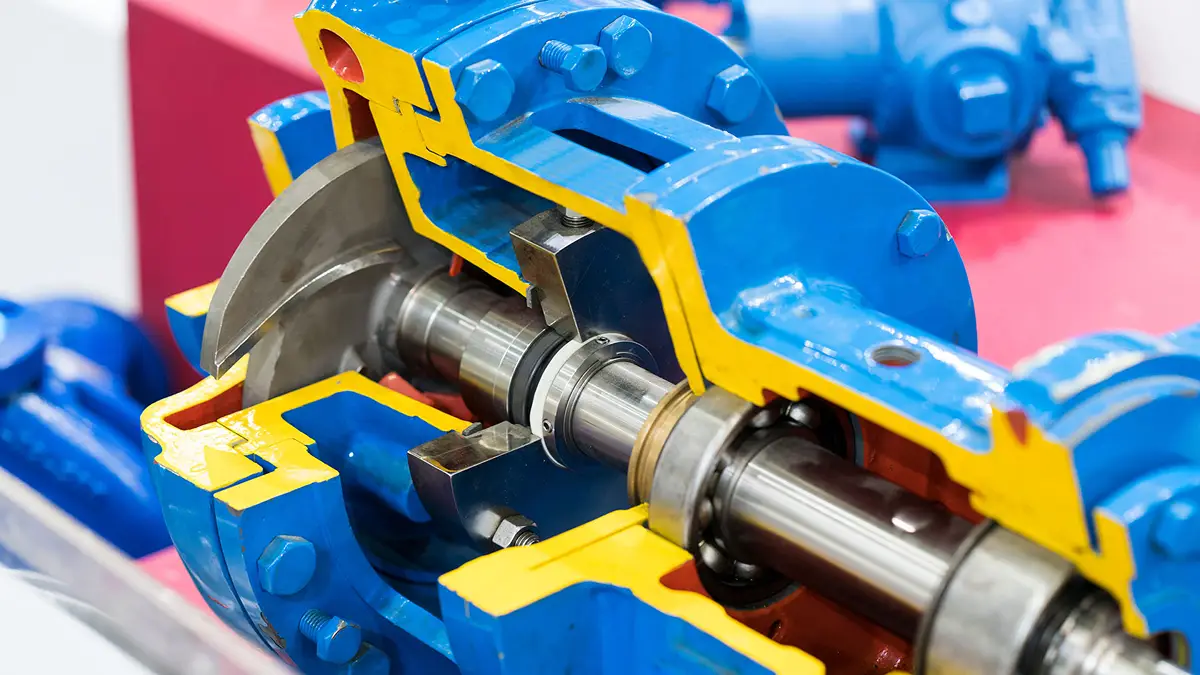

Key Components of Hydraulic Diaphragm Pumps

Pump Casing

A hydraulic diaphragm pump’s casing creates its external structure and offers the durability required to endure harsh industrial settings. It shields vital internal parts from deterioration, corrosion, and environmental harm. For long-term dependability and operational effectiveness, selecting the right casing material is essential, particularly in heavy-duty sectors like mining, oil & gas, and wastewater treatment.

Common materials used in pump casings include aluminum, cast iron, stainless steel, PVDF (polyvinylidene fluoride), and PTFE (polytetrafluoroethylene).

- Aluminum is lightweight and ideal for mobile or portable systems such as hydraulic dredging pumps, where mobility and ease of maintenance are key.

- Stainless steel and PTFE provide exceptional resistance to chemical corrosion, making them suitable for aggressive fluids and high-pressure environments in hydraulic diaphragm pumps.

- PVDF offers excellent mechanical strength and high resistance to acids, solvents, and oxidants, making it a preferred choice for chemical and wastewater applications.

Selecting the right casing material not only enhances the durability of hydraulic driven diaphragm pumps but also reduces downtime, repair frequency, and lifecycle costs.

Valves and Balls

The valves and balls in hydraulic diaphragm pumps control the directional flow of fluid and maintain consistent discharge pressure. Since they experience continuous motion and contact with sometimes abrasive or corrosive materials, their construction materials must be both durable and chemically resistant.

Common valve and ball materials include stainless steel, ceramic, and Santoprene®.

- Stainless steel is widely used for its toughness and corrosion resistance, particularly in oil and gas or marine applications.

- Ceramic provides superior hardness and abrasion resistance, ideal for handling dense slurries and sediments in hydraulic dredging pumps.

- Santoprene® combines elasticity with strong chemical stability, making it suitable for lighter industrial duties involving mild acids or alkalis.

Proper material selection ensures longer operational life, stable flow rates, and reduced wear across all types of hydraulic driven diaphragm pumps.

Seals and Gaskets

Seals and gaskets are essential for maintaining system integrity and preventing fluid leaks in hydraulic diaphragm pumps. These components are constantly exposed to varying pressures, temperatures, and chemical compositions, so the material choice must align with the specific application requirements.

Selecting appropriate seal and gasket materials helps prevent leakage, reduce maintenance requirements, and ensure the consistent performance of hydraulic diaphragm pumps under demanding conditions.

Choosing the Right Diaphragm Material

The Diaphragm’s Role

The diaphragm is the core component of a hydraulic diaphragm pump, serving as a flexible barrier separating the hydraulic fluid from the process fluid. Its movement enables precise fluid transfer while maintaining complete isolation between the two sides, preventing contamination and ensuring consistent, leak-free operation. Because the diaphragm experiences continuous flexing and pressure cycles, the material selection is critical to performance, durability, and operational efficiency.

In hydraulic driven diaphragm pumps, the diaphragm material determines how well the system can handle abrasive slurries, corrosive chemicals, or high-temperature conditions. For example, hydraulic dredging pumps rely on durable diaphragms capable of withstanding abrasive sediments and fluctuating pressures during dredging and sludge handling. Selecting the right diaphragm material ensures not only reliability but also long-term cost efficiency through reduced wear and maintenance.

Common Diaphragm Materials and Their Applications

Every diaphragm material has certain qualities that are appropriate for particular fluid kinds, temperatures, and pressures. The most popular materials and usual uses for hydraulic diaphragm pumps are as follows:

- Santoprene® – A thermoplastic elastomer that combines flexibility with strong chemical stability. It is ideal for applications involving abrasive slurries, high-cycle rates, and moderate temperatures. Santoprene diaphragms are widely used in mining and wastewater treatment, where durability and resilience are essential for continuous operation.

- PTFE (Teflon®) – Known for its outstanding chemical resistance and high-temperature tolerance (up to 220°C), PTFE is the go-to material for handling aggressive acids, solvents, and caustic fluids. It is commonly used in chemical processing and pharmaceutical industries, where purity and corrosion resistance are crucial.

- EPDM (Ethylene Propylene Diene Monomer) – An economical and adaptable choice that is resistant to alkaline solutions and water-based chemicals. EPDM diaphragms work effectively in the food, beverage, and agricultural industries where it’s critical that they work with non-oily materials.

- FKM (Viton®) – Offers superior resistance to hydrocarbons, oils, and high temperatures (up to 350°F). Though less flexible, it performs exceptionally well in oil and gas and refinery processes where exposure to petroleum-based fluids is constant.

- Hytrel® – A general-purpose diaphragm material combining excellent flex-life and abrasion resistance. It provides an economical solution for light industrial applications such as paints, coatings, and slurries.

- Metal Diaphragms (Inconel®, Hastelloy®, Titanium) –designed to withstand harsh conditions, such as high temperatures, pressures, or hostile chemicals. In industries where dependability is crucial, such as oil and gas, chemical processing, and even nuclear, metal diaphragms are commonly utilized.

In many hydraulic diaphragm pumps, a combination diaphragm, such as PTFE on the fluid side backed by EPDM or Santoprene on the hydraulic side, is used. This design provides the best balance of chemical resistance, flexibility, and mechanical strength.

Factors Influencing Diaphragm Material Selection

When selecting the optimal diaphragm for hydraulic diaphragm pumps, several factors must be evaluated to ensure compatibility and performance longevity:

- Fluid Composition – Determine whether the fluid is corrosive, abrasive, or viscous. The diaphragm material must resist chemical attack and mechanical wear. For example, PTFE handles aggressive acids, while Santoprene excels with abrasive slurries.

- Operating Pressure and Temperature – Higher pressures and temperatures require materials with superior tensile strength and thermal resistance, such as PTFE or metal alloys.

- Cycle Frequency – Pumps that operate continuously at high speeds benefit from elastomeric materials like Hytrel® or Santoprene®, which can withstand repetitive flexing.

- Regulatory and Hygiene Requirements – For applications in food, pharmaceutical, or municipal sectors, materials like PTFE or EPDM may be required to meet FDA or sanitary standards.

- Cost vs. Performance Balance – While premium materials like Inconel® or Viton® offer exceptional durability, balancing material cost with operational needs ensures the best ROI for long-term use.

Optimizing Performance Across Industries

Choosing the right diaphragm material allows hydraulic driven diaphragm pumps and hydraulic dredging pumps to perform reliably across diverse industries:

- Mining and Slurry Handling: Santoprene® or Hytrel® for abrasion and flex-fatigue resistance.

- Chemical Processing: PTFE or metal diaphragms for corrosion protection.

- Oil and Gas: Viton® or metal alloys for hydrocarbon exposure and high-heat conditions.

- Municipal and Wastewater Treatment: EPDM or Santoprene® for cost-effective, continuous service under moderate chemical exposure.

The good and right diaphragm material not only maximizes operational uptime but also minimizes energy loss and maintenance frequency, ensuring that hydraulic diaphragm pumps deliver dependable performance under the toughest conditions.

Material Considerations Based on Application

Mining and Heavy Industry

In mining and mineral processing, hydraulic diaphragm pumps are indispensable for transferring abrasive slurries, tailings, and corrosive liquids. These environments place extreme mechanical and chemical stress on pump components, making material selection crucial for ensuring durability and efficiency.

For such demanding applications, Santoprene® diaphragms are often the preferred choice due to their excellent abrasion resistance and flexibility under continuous operation. Casings made from stainless steel or cast iron provide the necessary structural strength to withstand high pressures and particulate-heavy fluids. In abrasive slurry handling and sediment removal, hydraulic dredging pumps equipped with Santoprene® or Hytrel® diaphragms perform exceptionally well, maintaining steady flow and minimizing maintenance downtime.

Mining operations that rely on hydraulic driven diaphragm pumps benefit from their ability to handle solids-laden fluids without valve clogging or diaphragm fatigue.

Chemical Processing and Pharmaceutical Industries

Chemical manufacturing, pharmaceutical production, and specialty processing require hydraulic diaphragm pumps designed with materials that offer superior chemical resistance and contamination control. These applications often involve aggressive fluids such as acids, caustics, and solvents, making the correct selection of diaphragm and casing materials critical.

Because of their remarkable resistance to corrosive chemicals and high temperatures, PTFE (Teflon®) diaphragms are the industry standard in chemical processing. They offer unparalleled defense against chemical deterioration when combined with PVDF or stainless steel casings. Hydraulic driven diaphragm pumps with PTFE diaphragms guarantee accurate fluid transmission in cleanroom or pharmaceutical settings without the possibility of cross-contamination.

Hydraulic diaphragm pumps made from chemically inert materials reduce maintenance costs and increase production uptime, whether used for chemical dosing, solvent transfer, or sterile operations.

Oil and Gas Industry

The oil, gas, and petrochemical sectors demand high-performance hydraulic diaphragm pumps capable of handling hydrocarbons, lubricants, and other oil-based fluids under extreme pressures and temperatures. Material compatibility is essential to prevent degradation and maintain efficiency in these aggressive environments.

FKM (Viton®) diaphragms are the preferred option for hydraulic driven diaphragm pumps used in refineries and offshore platforms due to their outstanding resistance to oils, fuels, and high heat, withstanding temperatures up to 350°F (177°C). For even harsher applications, metal diaphragms made from Inconel®, Hastelloy®, or Titanium provide superior strength and thermal stability, ensuring continuous operation without deformation or chemical attack.

The pump’s resistance to corrosive vapors and changing pressures is further enhanced by casing materials such as carbon steel and stainless steel. Hydraulic dredging pumps made of corrosion-resistant metals operate dependably in submerged or sludge-handling activities, providing the strength and durability needed in deep-water and onshore fluid transfer systems.

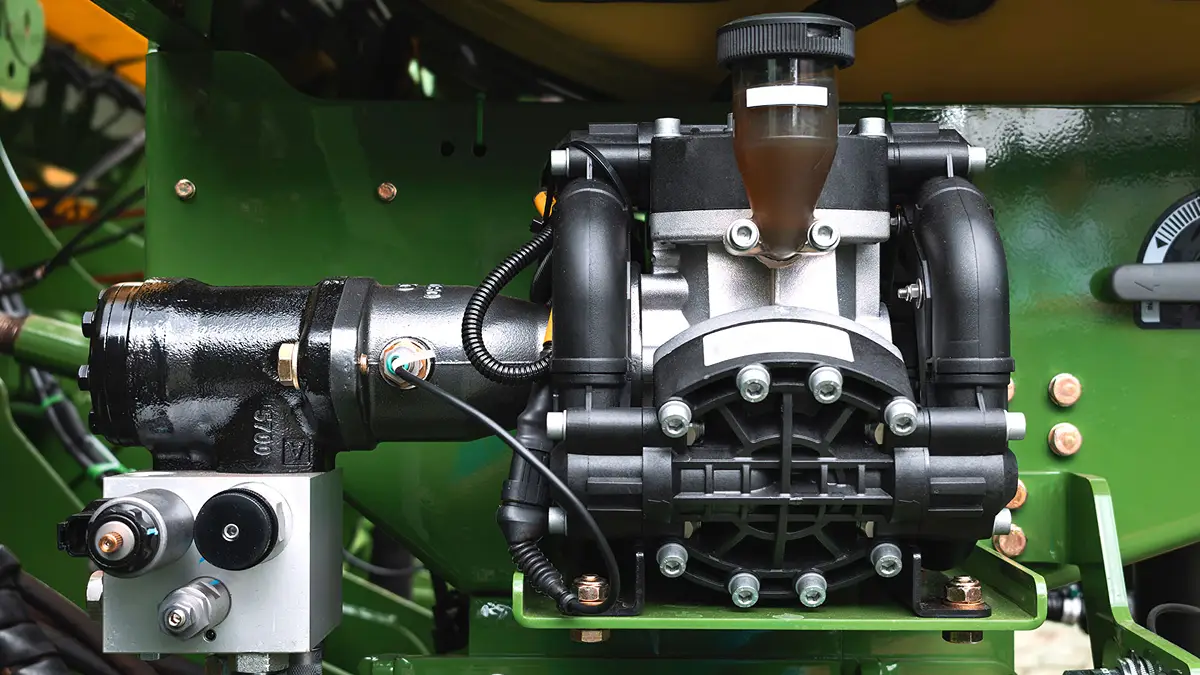

Municipal, Environmental, and Wastewater Applications

In municipal water management, wastewater treatment, and environmental remediation, hydraulic diaphragm pumps play a key role in transferring sludge, sludge thickeners, and chemical dosing solutions. These operations demand pumps that can handle solids, corrosive liquids, and varying viscosities without frequent maintenance.

EPDM and Santoprene® diaphragms are commonly used in these sectors for their ability to resist water-based chemicals and alkalines. When combined with stainless steel or PVDF casings, they deliver long-lasting performance in both continuous and intermittent service. Hydraulic dredging pumps are particularly valuable for dewatering lagoons, removing silt, and managing biosolids, where their abrasion-resistant construction prevents premature wear.

Hydraulic driven diaphragm pumps are increasingly used by government agencies, municipal contractors, and wastewater treatment plants due to their energy efficiency, low maintenance requirements, and ability to work in submerged or semi-submerged situations. The appropriate material selection assures dependability, reduces leakage, and decreases total operating costs, which is crucial for infrastructure systems that must operate around the clock.

4. How to Select the Best Materials for Your Hydraulic Diaphragm Pump

Step-by-Step Material Selection Guide

Selecting the correct materials for hydraulic diaphragm pumps is critical to achieving maximum efficiency, durability, and cost-effectiveness. Because these pumps are often deployed in tough environments, from mining and dredging sites to chemical and wastewater facilities, every component must be matched to the fluid type, operating conditions, and performance requirements. Proper material selection ensures that hydraulic driven diaphragm pumps and hydraulic dredging pumps continue to deliver consistent, reliable operation with minimal downtime.

Here’s a step-by-step guide to choosing materials that can help hydraulic diaphragm pumps last longer and perform better in challenging industrial applications.

1. Understand the Nature of the Fluid

The first step in selecting materials for hydraulic diaphragm pumps is understanding the characteristics of the liquid being pumped. Fluids can be abrasive, corrosive, viscous, or contain suspended solids, all of which impact material choice.

- Corrosive Fluids: Use PTFE or PVDF diaphragms and casings to resist acids, caustics, and solvents.

- Abrasive Slurries: Opt for Santoprene® or Hytrel® diaphragms, commonly used in mining and dredging operations with hydraulic dredging pumps.

- Oil-Based Liquids: Choose Viton® or metal diaphragms for hydraulic driven diaphragm pumps in oil and gas processing, ensuring superior resistance to hydrocarbons.

Matching material to fluid composition ensures optimal pump life, reduced wear, and stable output performance.

2. Evaluate Viscosity and Solids Content

Viscosity directly influences how hydraulic diaphragm pumps perform. Fluids with higher viscosity or containing suspended solids require stronger, more flexible diaphragm materials to maintain flow consistency.

- Thick or Viscous Fluids: Use reinforced Santoprene® or EPDM diaphragms to handle slower flow rates efficiently.

- Slurries and Sediments: In hydraulic dredging pumps, abrasion-resistant diaphragms paired with durable valve seats help maintain smooth operation even in sediment-heavy conditions.

- Low-Viscosity Liquids: PTFE diaphragms work best for thin, chemical-based fluids, preventing leakage and cross-contamination.

Selecting materials suited to the viscosity of the fluid ensures hydraulic driven diaphragm pumps operate smoothly and efficiently under varying load conditions.

3. Assess Chemical Compatibility

Every component in hydraulic diaphragm pumps, from the casing to the diaphragm and seals, must be compatible with the chemicals it contacts. Incompatible materials can degrade quickly, leading to leakage, loss of pressure, and system failure.

- Aggressive Chemicals: PTFE and PVDF are ideal for handling acids, alkalis, and solvents in industrial chemical processes.

- Hydrocarbons and Oils: Viton® or metal diaphragms in hydraulic driven diaphragm pumps offer superior resistance to fuels and lubricants.

- Water-Based Fluids: EPDM or Santoprene® provides dependable resistance to alkalis, salts, and mild chemicals, making them suitable for municipal and wastewater applications.

Conducting a compatibility review ensures that hydraulic diaphragm pumps maintain consistent performance, minimizing replacement costs and downtime.

4. Consider Flow Rate and Pressure Requirements

Flow rate and discharge pressure are key performance parameters when selecting materials for hydraulic diaphragm pumps. These values determine how the diaphragm and casing will endure continuous stress during operation.

- High-Pressure Applications: Metal diaphragms (Inconel®, Titanium, Hastelloy®) and stainless-steel casings are best for high-pressure hydraulic driven diaphragm pumps used in oil, gas, and marine environments.

- Moderate Pressure Systems: PTFE and Santoprene® diaphragms provide a balanced combination of flexibility and durability for hydraulic diaphragm pumps handling water, chemicals, or slurries.

- Low-Pressure Dredging: Hydraulic dredging pumps benefit from abrasion-resistant elastomeric diaphragms that maintain flow without fatigue under heavy sediment loads.

5. Factor in Temperature Conditions

Temperature extremes significantly influence the performance of hydraulic diaphragm pumps. Materials must be chosen to withstand both ambient and operating temperatures without compromising flexibility or chemical resistance.

- High-Temperature Environments: PTFE, Viton®, or metal diaphragms are best for applications in oil refineries and chemical plants where heat exceeds 200°C.

- Moderate Temperature Operations: Santoprene® and EPDM perform well up to 100°C, making them suitable for wastewater treatment and industrial slurry pumping.

- Cold or Variable Climates: Flexible materials like Hytrel® prevent cracking and fatigue in hydraulic driven diaphragm pumps operating outdoors or in fluctuating temperatures.

Selecting the right material based on temperature conditions prevents premature wear and ensures hydraulic diaphragm pumps remain dependable year-round.

6. Align Material Selection with Service Type

Finally, material choices should reflect the service type, whether the hydraulic diaphragm pump will operate continuously, intermittently, or on demand.

- Continuous Duty: Santoprene® and Hytrel® provide excellent flex life, ideal for nonstop operations like mining slurry transfer or wastewater processing.

- Intermittent Duty: PTFE-backed diaphragms are suited for batch dosing or chemical injection systems, typical in hydraulic driven diaphragm pumps.

- On-Demand Service: In dredging or dewatering operations, hydraulic dredging pumps with abrasion-resistant elastomers deliver high reliability with minimal maintenance.

Matching materials to duty cycles ensures consistent performance and reduces fatigue-related failures in all types of hydraulic diaphragm pumps.

Maximizing Performance and ROI Through Smart Material Choices

Selecting the best materials for hydraulic diaphragm pumps, hydraulic driven diaphragm pumps, and hydraulic dredging pumps requires a detailed understanding of fluid characteristics, operating pressures, and environmental conditions. The right combination of diaphragm, seal, valve, and casing materials extends equipment life, reduces maintenance intervals, and delivers superior return on investment, ensuring pumps perform efficiently and reliably in the world’s most demanding industries.

Selecting the Right Materials to Maximize Pump Performance and Longevity

For hydraulic diaphragm pumps, choosing suitable supplies and parts is not only a technical choice; it’s also a crucial one that affects the overall cost of ownership, performance effectiveness, and long-term dependability. Pumps must function in extremely demanding environments in sectors such heavy manufacturing, wastewater treatment, mining, and oil & gas.

When engineered with precision and built using the correct materials, hydraulic diaphragm pumps deliver years of dependable service, even in environments where other pump types fail. For high-pressure or chemically aggressive operations, hydraulic driven diaphragm pumps offer superior control, exceptional accuracy, and minimal pulsation.

Meanwhile, in dredging, sediment removal, and sludge handling, hydraulic dredging pumps have proven invaluable for their durability and capacity to manage abrasive mixtures. When constructed with abrasion-resistant diaphragms, stainless steel casings, and corrosion-proof seals, these pumps maintain efficiency even in the most extreme marine or mining conditions. Choosing high-quality, application-specific materials ensures that hydraulic dredging pumps operate longer, resist wear, and deliver consistent results.

Ultimately, optimizing material selection for hydraulic diaphragm pumps, hydraulic driven diaphragm pumps, and hydraulic dredging pumps allows industries to achieve higher productivity, lower lifecycle costs, and superior operational stability.